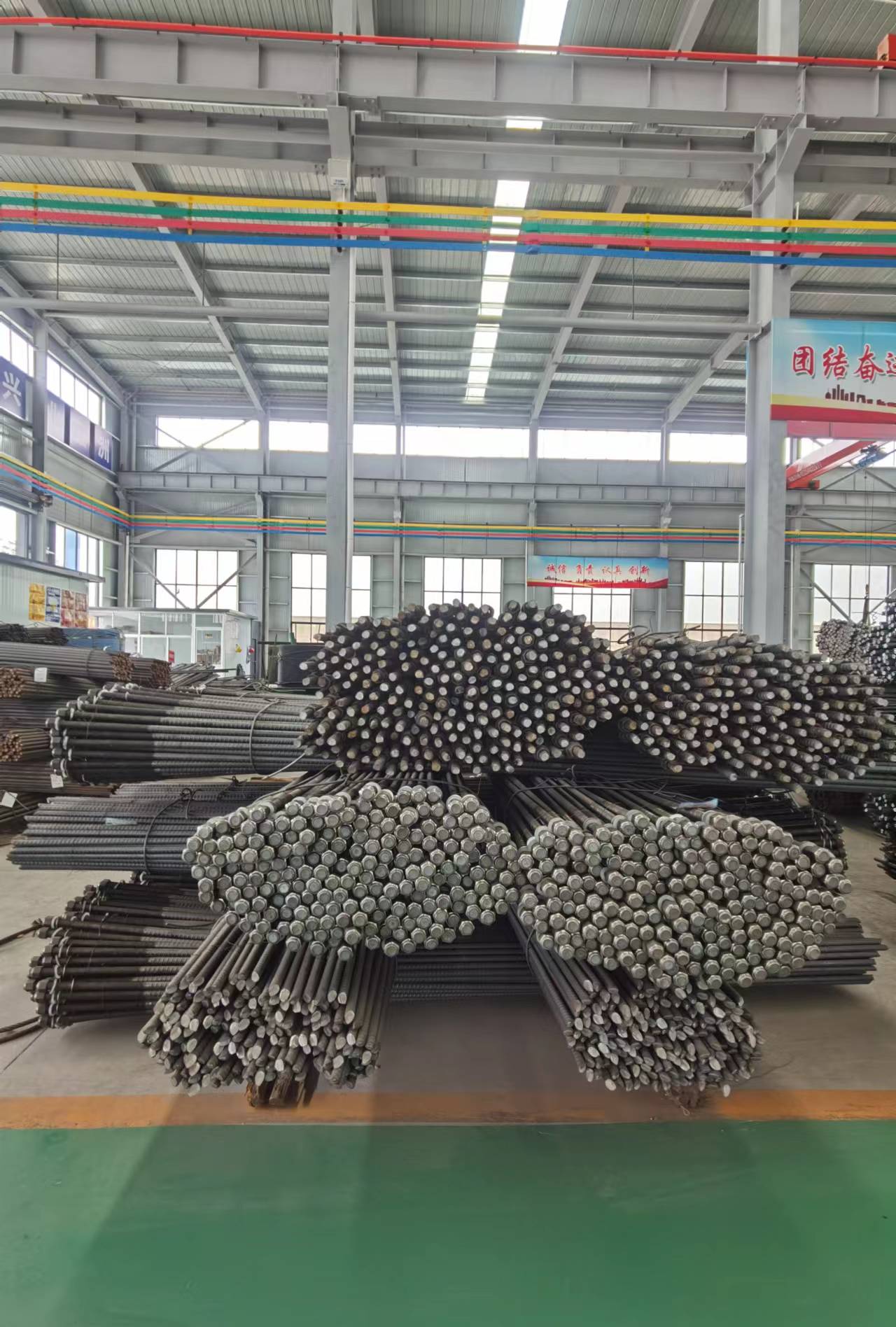

Disc Anchors Threaded Rod

Geological complexities are no match for Disc Anchors Threaded Rod. They adapt seamlessly to various terrains, from rocky landscapes to seismic zones. Each rod serves as a steadfast sentinel, conquering environmental forces and providing a reliable anchor for progress.The threaded design of these rods streamlines construction, allowing for seamless integration with other components. Architects and engineers can explore uncharted realms of design, confident that the foundational support of Disc Anchors Threaded Rod empowers their visions.

Safety takes center stage with Disc Anchors Threaded Rod. By minimizing the risk of structural shifts and collapses, these rods prioritize the well-being of inhabitants and workers alike. The result is a secure and stable environment that fosters productivity and peace of mind.Disc Anchors Threaded Rod are more than a structural component; they are a catalyst for innovation. Architects and engineers leverage their strength and adaptability to pioneer new designs, pushing the boundaries of what's possible and creating structures that inspire awe.

Disc bolt is a commonly used support material for underground engineering, which has the following advantages:

Good bearing capacity: disc bolt is made of high-strength material, has high tensile strength and carrying capacity, can withstand large loads, to ensure the stability of underground engineering.

Good stability: The disc anchor expands after grouting in the borehole and forms friction with the surrounding soil, so as to realize the support of underground engineering, which can effectively improve the stability of the soil and reduce the surface settlement.

Convenient construction: The installation process of disc bolt is relatively simple, only need to insert the bolt into the pre-drilled hole, and grouting expansion can complete the installation, easy to operate, suitable for various geological conditions.

Flexible and adjustable: the length of the disc bolt can be adjusted according to specific needs, and can be customized according to the depth and needs of underground engineering to improve its adaptability and flexibility.

Strong durability: disk anchors are usually made of corrosion-resistant materials, which have good corrosion resistance and can be used stably for a long time under different environmental conditions to extend the life of underground projects.

To sum up, disc bolt has the advantages of strong bearing capacity, good stability, convenient construction, flexible and durable, and is widely used in underground engineering support, such as tunnels, subways, underground parking lots and other projects.

Technical Parameter | ||||||||

Performance Material Specification | Rod outer diameter(mm) | carrying capacity(kn) | ||||||

Nominal size | Allow partial dragons | HRB335 | HRB400 | HRB500 | HRB600 | HRB335 | ||

standard | carrying capacity | |||||||

φ-16 | 16 | +0.3/-0 | ≧100 | ≧120 | ≧135 | 120x120x5 | ≧100 | |

φ-18 | 18 | +0.3/-0 | ≧126 | ≧150 | ≧172 | ≧206 | 150x150x5 | ≧135 |

φ-20 | 20 | +0.3/-0 | ≧157 | ≧180 | ≧210 | ≧260 | 150x150x6 | ≧170 |

φ-22 | 22 | +0.3/-0 | ≧190 | ≧225 | ≧250 | ≧310 | 150x150x8 | ≧230 |

Anchor Characteristics of Disc Anchors Threaded Rod:

1. superficially it restricts the rock and soil body from the original body.

2. Macroscopically it increases the cohesion of the rock and soil body.

3. Anchor rods are not only used in mines, but also used in engineering technology for active reinforcement of slopes, tunnels, dams and so on.

4. Anchor is the basic component of tunnel support in contemporary underground mining, which binds the perimeter rock of the tunnel together, so that the perimeter rock supports itself.

Advantages of Disc Anchors Threaded Rod

1. Anchor end and fastening end do not require machining.

2. Equal strength for the whole length, high material utilization.

3. Large anchorage force.

4. Pre-stressing hot piece is provided, easy to control the installation quality.

5. Fast installation speed.

6. It is made according to the rotating direction of the digging tool, so that the anchor will not exit during the operation.

Product Selection and Working Conditions of Disc Anchors Threaded Rod:

1. Product selection: support designers according to the roadway section of the surrounding rock geological conditions to detect the surrounding rock to pressure parameters, and then combined with practical experience, can choose different specifications of the anchor.

2. Using working conditions: Users should have drilling and installation equipment, resin anchors and so on. In order to increase the effect of support, after the installation of anchor rods, plus the installation of anchor net anchor cable and slurry. The drilling size and depth should be used according to the specifications of anchor rods and anchoring agents; thinking about the electricity conditions of the web page, it's far endorsed to prioritize the use of pneumatic anchor drilling rigs or hydraulic anchor drilling rigs in order that the drilling and installation are achieved within the equal machine: for the usage of excessive rock hardness web page choice of the 7655 wind hammer drilling, pneumatic coal drilling and stirring set up. stirring installation of rated output pace ≥ four hundred rpm output torque,for the full-length anchoring should be 2 60Nm; for end anchoring should be 240Nm machine.