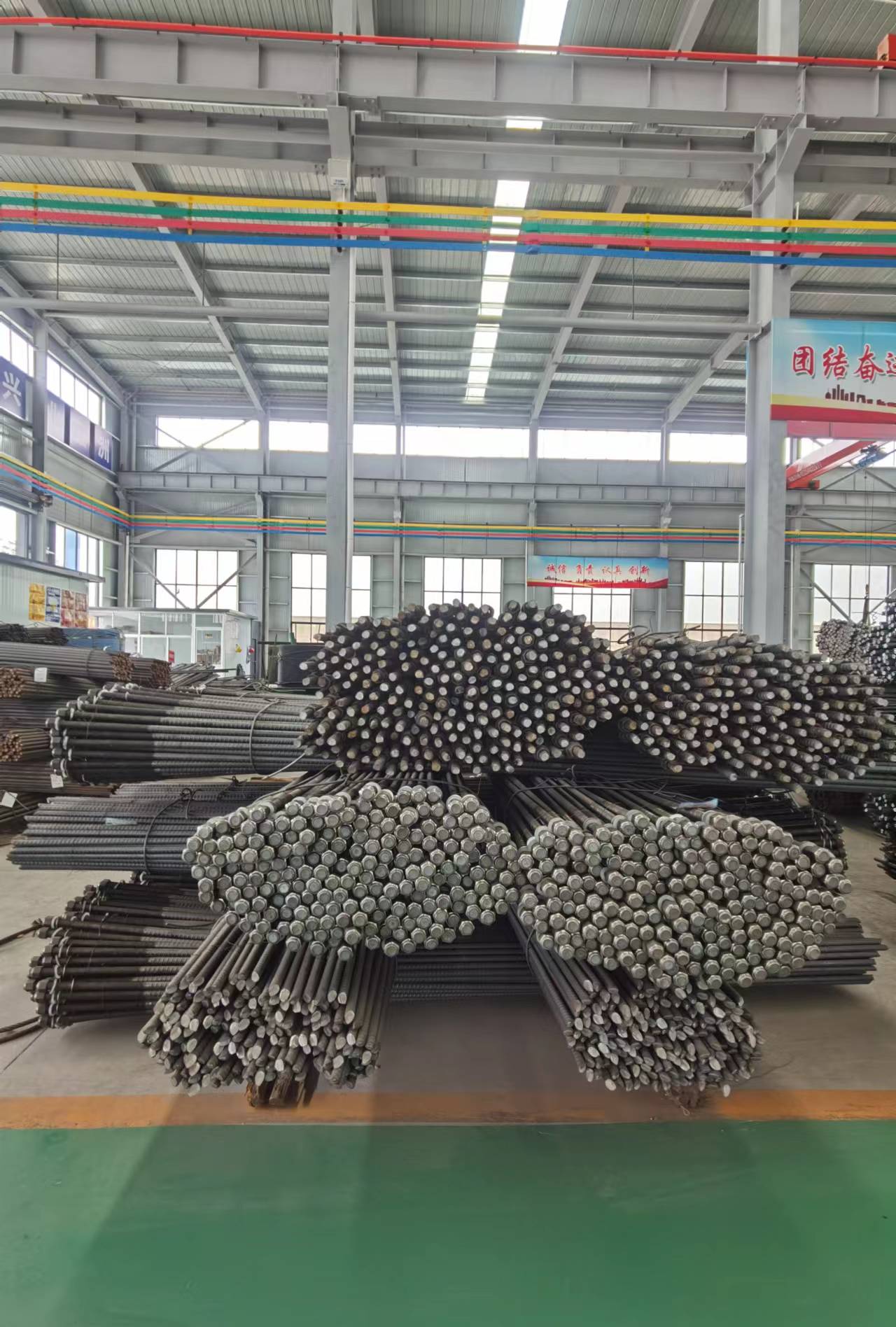

Mining Threaded Rod Concrete Anchors

Introducing our threaded anchor rods – the spine of structural integrity. crafted with precision and fortified with resilience, those rods make certain your initiatives stand robust in opposition to the check of time. raise your structures with the power of threaded anchor rods.

Every thread, a testomony to meticulous craftsmanship. our threaded anchor rods are meticulously designed to seamlessly interlock, growing a symphony of energy that weaves all through your structures. find out the harmony of precision engineering.

The threaded anchor without longitudinal rib is a completely unique and high-electricity steel rod particularly engineered to decorate the stability and fortification of underground and civil engineering tasks. with its easy threaded floor and absence of longitudinal ribbing, this anchor offers seamless integration and easy reference to different rods or structural elements, forming a reliable and relaxed support gadget.Its versatility and reliability make it an essential component for reinforcing various construction ventures.

Technical Parameter | ||||||||

Performance Material Specification | Rod outer diameter(mm) | carrying capacity(kn) | ||||||

Nominal size | Allow partial dragons | HRB335 | HRB400 | HRB500 | HRB600 | HRB335 | ||

standard | carrying capacity | |||||||

φ-16 | 16 | +0.3/-0 | ≧100 | ≧120 | ≧135 | 120x120x5 | ≧100 | |

φ-18 | 18 | +0.3/-0 | ≧126 | ≧150 | ≧172 | ≧206 | 150x150x5 | ≧135 |

φ-20 | 20 | +0.3/-0 | ≧157 | ≧180 | ≧210 | ≧260 | 150x150x6 | ≧170 |

φ-22 | 22 | +0.3/-0 | ≧190 | ≧225 | ≧250 | ≧310 | 150x150x8 | ≧230 |

Anchor Characteristics:

Superficially, it confines the rock and soil body, limiting its expansion from the original state.

On a macroscopic degree, it enhances the concord of the rock and soil frame, selling structural integrity.

Anchor rods locate versatile packages beyond mining, extending to engineering technologies that actively toughen slopes, tunnels, dams, and different projects.

Anchors serve as fundamental components in modern underground mining tunnel support, effectively bonding the perimeter rock of the tunnel, enabling self-support of the surrounding rock structure.

Product Selection and Working Conditions:

Product Selection:Aid designers will assess the geological conditions of the encircling rock and determine the strain parameters to pick the ideal anchor specifications. this choice-making method consists of realistic enjoy to ensure an top of the line desire. utilising working conditions: customers ought to own drilling and installation system, in addition to resin anchors, amongst different essentials.To enhance support effectiveness, after installing anchor rods, complement the setup with anchor nets, anchor cables, and slurry. The drilling size and depth should align with the specifications of anchor rods and anchoring agents. Considering site power capabilities, it is advisable to prioritize pneumatic or hydraulic anchor drilling rigs that facilitate drilling and installation in a single operation. For websites with excessive rock hardness, opt for the 7655 wind hammer drilling, pneumatic coal drilling, and stirring set up. stirring set up necessitates a rated output pace of ≥ 400 rpm and an output torque of 260nm for complete-length anchoring and 240nm for cease anchoring.

Advantages

1. Anchor end and fastening end do not require machining.

2. Equal strength for the whole length, high material utilization.

3. Large anchorage force.

4. Pre-stressing warm piece is provided, clean to control the set up nice.

5. Rapid installation pace.

6. It's far made in line with the rotating route of the digging tool, so that the anchor will no longer go out in the course of the operation.