Mining Rock Bolts

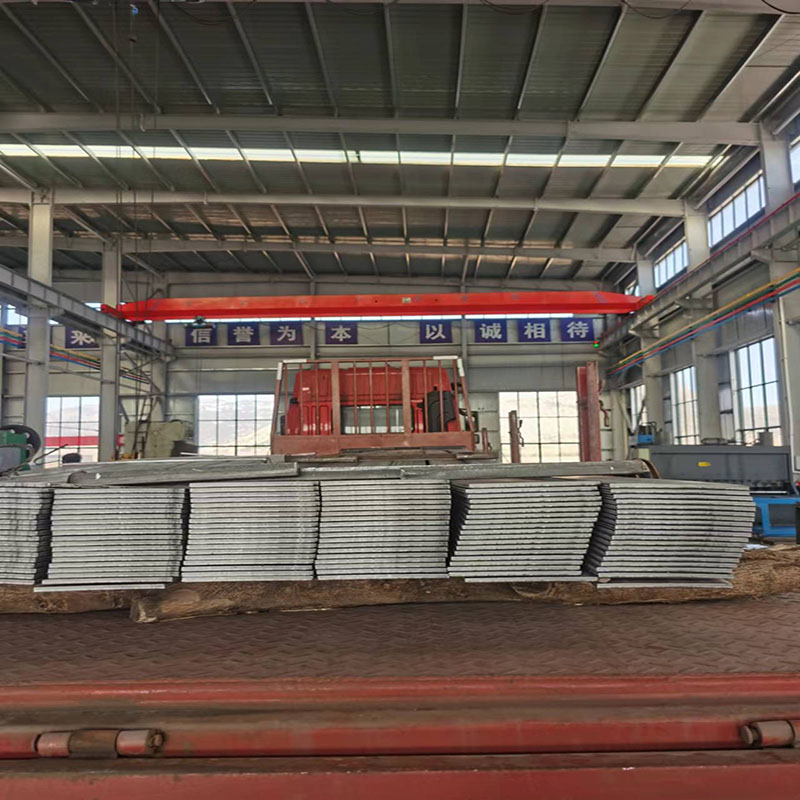

A Mining Support Anchor plate is a device used to support and reinforce rock structures in a mine or mining project. These plates are usually made of metal or other strong materials that are strong and stable enough to bear the pressure and weight of the rock. The support anchoring plate is fixed to the rock surface or structure by anchoring equipment to provide support and reinforcement to ensure safety and stability during the mining process.

Mining Rock Bolt Support Plate

Mining rock bolting support plates are a type of support equipment used in mining and rock engineering and are commonly used to reinforce rock structures or extruded structures for support. These support plates are usually made of metal and have the strength and stability to be bolted to the surface of the rock or extruded structure. Bolted support plates play an important role in mining and underground engineering, helping to ensure safe and stable operation.

Specifications and parameters:

Pallet Size(mm) | carrying capacity (kn) (kn) | Pallet Size(mm) | carrying capacity(kn) | note |

120x120x5 | ≧100 | 200x200x10 | ≧360 | Partial specifications |

120x120x6 | ≧115 | 200x200×12 | ≧420 | |

120x120x8 | ≧130 | 250x250×8 | ≧320 | |

150x150×5 | ≧135 | 250x250x10 | ≧400 | |

150x150x6 | ≧170 | 250×250x12 | ≧440 | |

150x150x8 | ≧230 | 300x300x10 | ≧420 | |

150x150x10 | ≧290 | 300x300x12 | ≧480 | |

120x120x10 | ≧260 | 300x300x14 | ≧520 |

Anchor Tray Description:

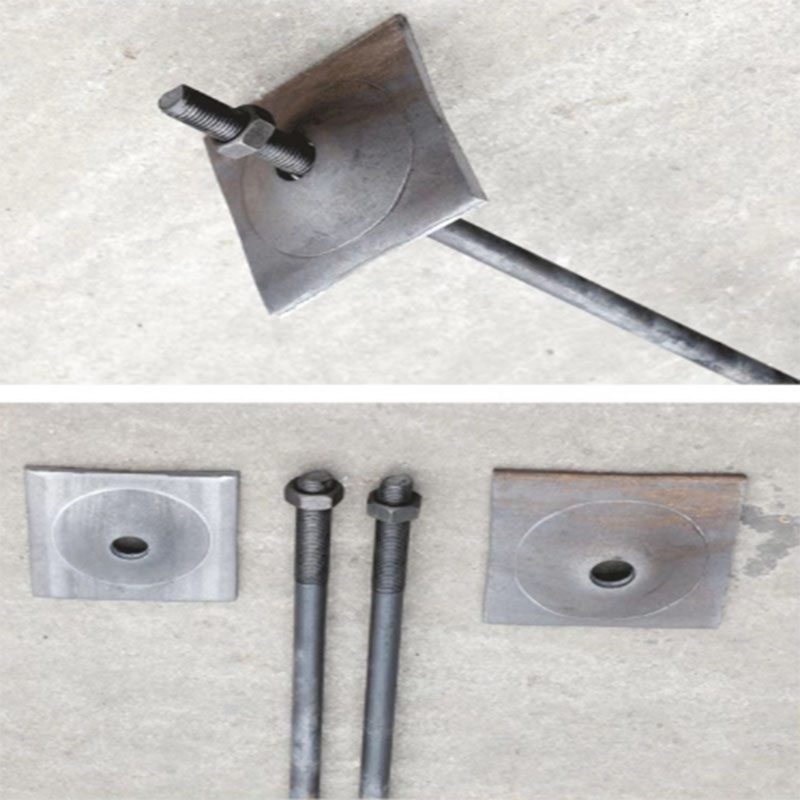

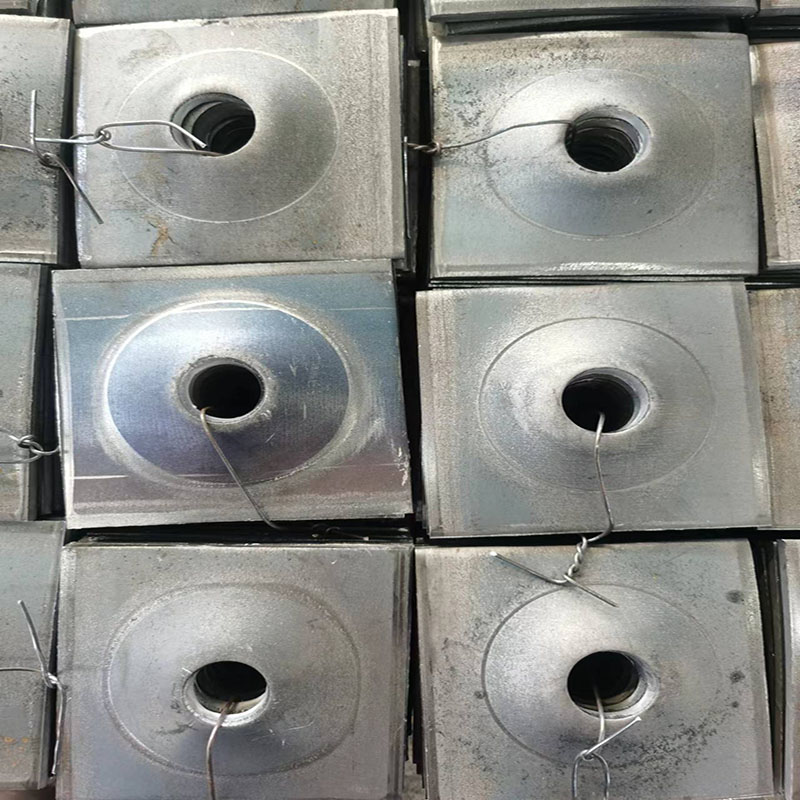

Mining pallet a kind of pallet used for mine roadway, tunnel, especially coal mine roadway anchor support, the center of the pallet has holes for anchor rods to pass through, the central part of the hollow spherical bump, there can be a platform at the top of the spherical bump, the pallet can be made of steel plate or cast iron, the pallet made of cast iron can have reinforcing bars around the spherical bump.

As an important part of the anchor support system, the performance of the anchor tray directly affects the support effect of the anchor. The role of the tray is to transfer the thrust force generated by the nut locking torque to the top gang to generate the initial anchor force, and at the same time transfer the pressure of the roadway top gang to the anchor rod to generate the working resistance, which together reinforce the surrounding rock and stop the displacement of the roadway top gang. Therefore, when selecting the tray, firstly, it is necessary to satisfy the matching of the anchor tray and the anchor rod body in terms of strength, so as to avoid the phenomenon of anchor perforation caused by the insufficient strength of the anchor tray. The second is to meet the matching between the anchor tray and the anchor rod body in the support structure, to avoid the uneven force on the anchor rod body and nut due to the mismatch between the anchor rod body and the tray in the support structure, which affects the support effect of the roadway.

Anchor pallet advantages:

Adopting high-strength plate; Adopting special shape design with good stress effect, lightweight and easy to install; Improving the surface control effect; Improving the internal stress state of the anchor pallet, which has the advantages of strong bearing capacity and material saving.

Related News

Submitted successfully

We will contact you as soon as possible