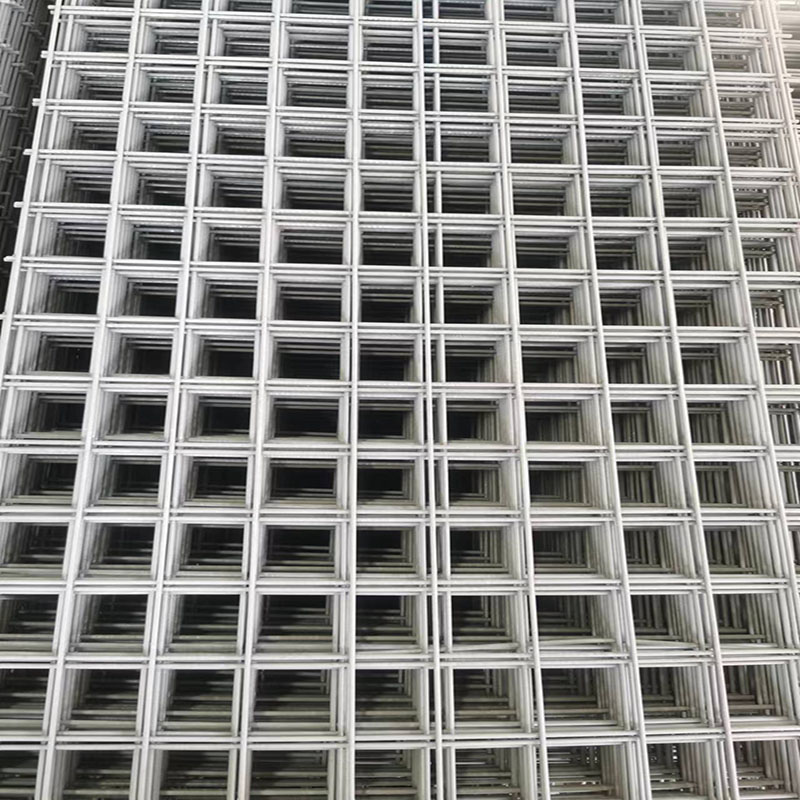

High Quality Heavy Duty Wire Mesh

Advantages:

(1) Good support effect. It can improve the strength of roadway surrounding rock by improving the self-stabilizing ability of surrounding rock, and it has better effect on layer-forming and fissure-containing rock body;

(2) low labor intensity and fast construction speed. The installation of an anchor can be completed in a few minutes, which is advantageous compared with the way of laying swan and erecting a shed. (3) Wide range of application. By changing the anchor length, diameter, inter-row spacing, and truss connection at the end of the anchor, combined with anchor cable, ladder beam, spray concrete, etc., it basically applies to most ranges.

The role of the anchor net

Anchor mesh support is a kind of support method that is adopted more in deep foundation pit support engineering at present. It is the abbreviation of joint support of sprayed concrete, anchor rods and reinforcing mesh. As an advanced support and reinforcement technology, it has been widely and successfully applied at home and abroad in the geotechnical high slope and large-span underground projects, especially under the adverse geological conditions. Spray anchor network support, is through the construction of a certain length and distribution of anchors in the geotechnical body, and the geotechnical body together to form a composite body, to make up for the lack of strength of the geotechnical body and play the role of anchoring and pulling the geotechnical body, so that the geotechnical body of its own structural strength potential to give full play to ensure that the stability of the slope. The slope is set with reinforced mesh sprayed concrete, which plays the role of restraining the deformation of the slope and makes the whole slope form a whole. The process flow of its construction is as follows: excavation of earth and rocks, slope repair → drilling → anchor rod (cable) installation → pressure grouting → hanging the reinforcing mesh → welding reinforcing bars → shotcrete → (anchor cable pre-stressing tensioning, anchoring) → excavation of the lower layer. For unstable soil layer, after excavation and slope repair, the first concrete spraying should also be added.

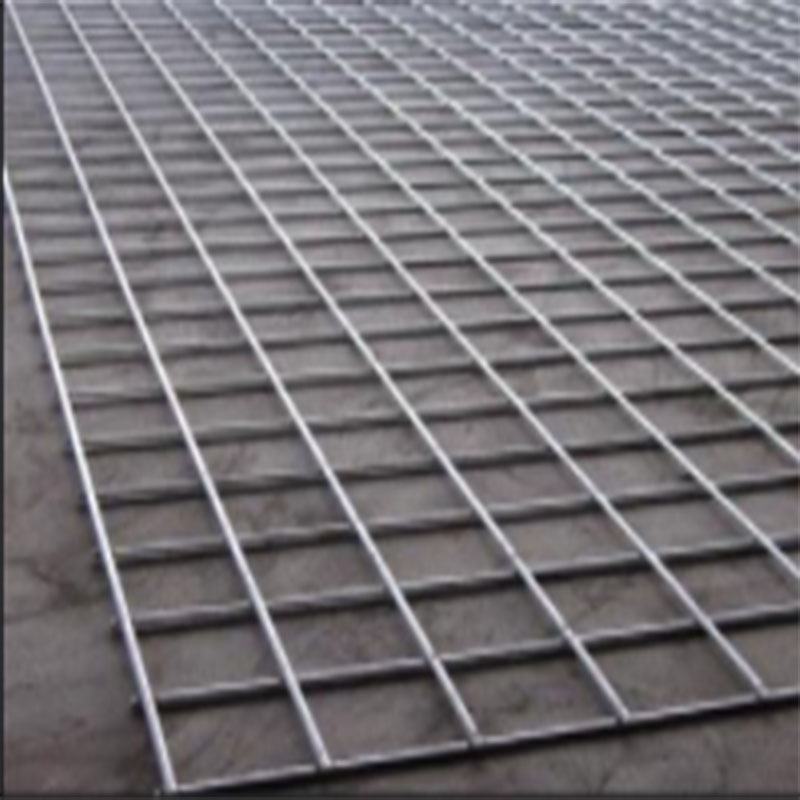

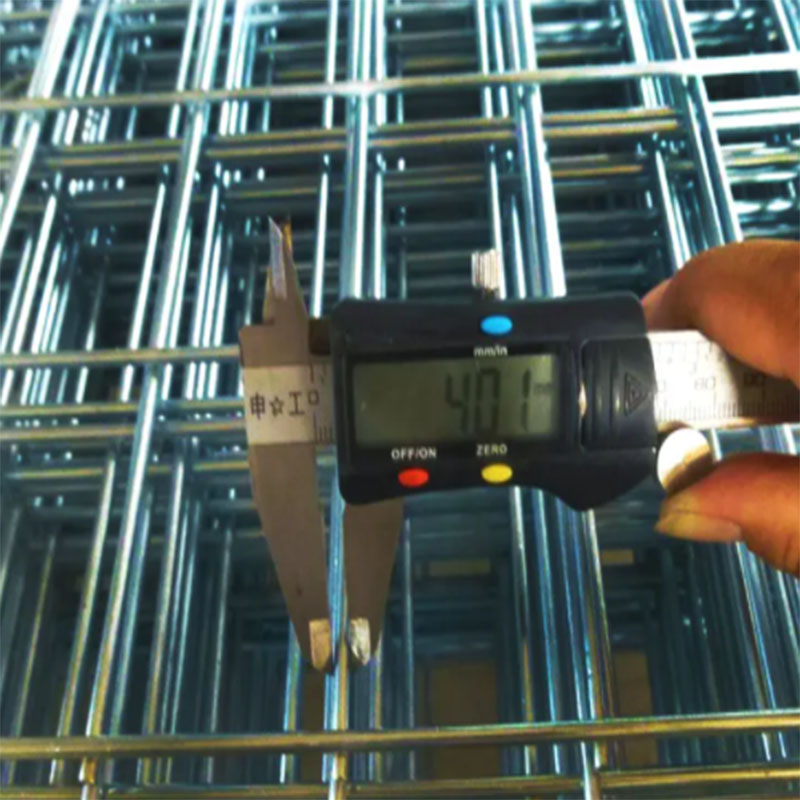

Parameters of reinforced mesh | |||

Mesh Size | Wire Diameter | Panel Sizes | |

In Inch | In MM | In MM | Common sizes: 2.2 x 5.8m, 2.0 x 2.9m

Other sizes can be made as request |

2” x 4” | 50 x 100mm | 4.0mm – 10.0mm | |

3” x 4” | 75 x 100mm | 4.0mm – 10.0mm | |

4” x 4” | 100 x 100mm | 4.0mm – 12.0mm | |

6” x 6” | 150 x 150mm | 4.0mm – 12.0mm | |

8” x 8” | 200 x 200mm | 4.0mm – 12.0mm | |

Reinforcing Mesh Specifications:

Reinforcing steel mesh reinforcement diameter is 4-14mm, of which 0.5mm progressive diameter can be used. Considering the transportation conditions, the length of welded mesh should not exceed 12m, and the width should not exceed 3.4m.The spacing of reinforcement bars in the direction of welded mesh fabrication (or longitudinal reinforcement) is suitable to be 100, 150, 200mm, and the spacing of reinforcement bars in the other direction is generally 100, 150, 200, 300mm, and sometimes it can be up to 400mm.When the longitudinal and transversal reinforcement bars of the welded mesh are all single reinforcement bars, the nominal diameter of the finer reinforcement bars The nominal diameter of the finer reinforcement should be not less than 0.6 times the nominal diameter of the thicker reinforcement, i.e. dmin ≥ 0.6damx. The shear resistance of the welded mesh weld joints (in N) should be not less than the product of 150 and the nominal cross-sectional area of the thicker reinforcement (in mm2).

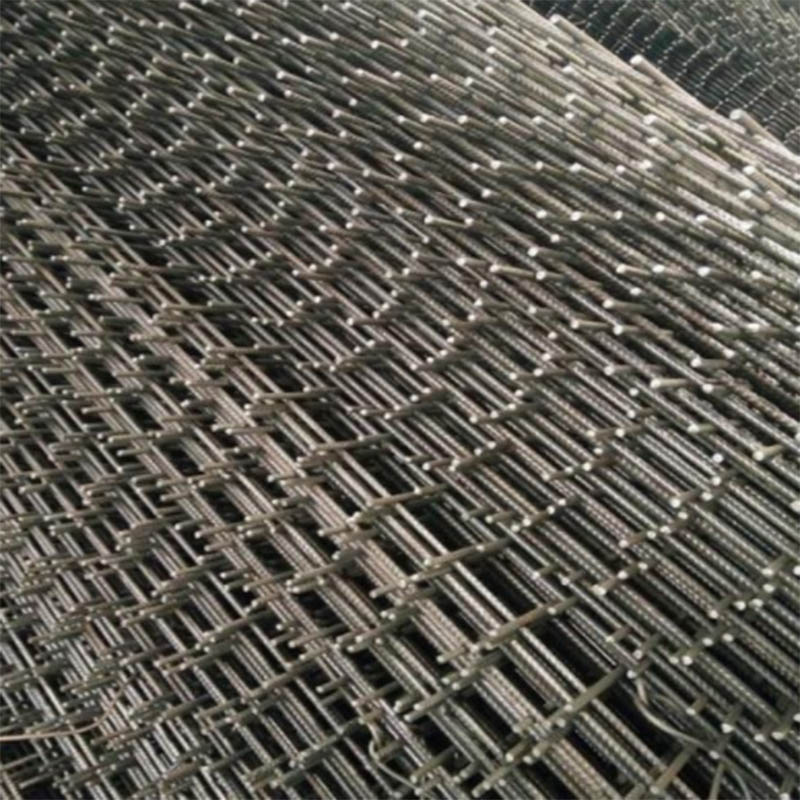

Reinforcing steel mesh materials mainly include:

cold rolled ribbed (bare round) reinforcing steel mesh, hot rolled ribbed (bare round) reinforcing steel mesh

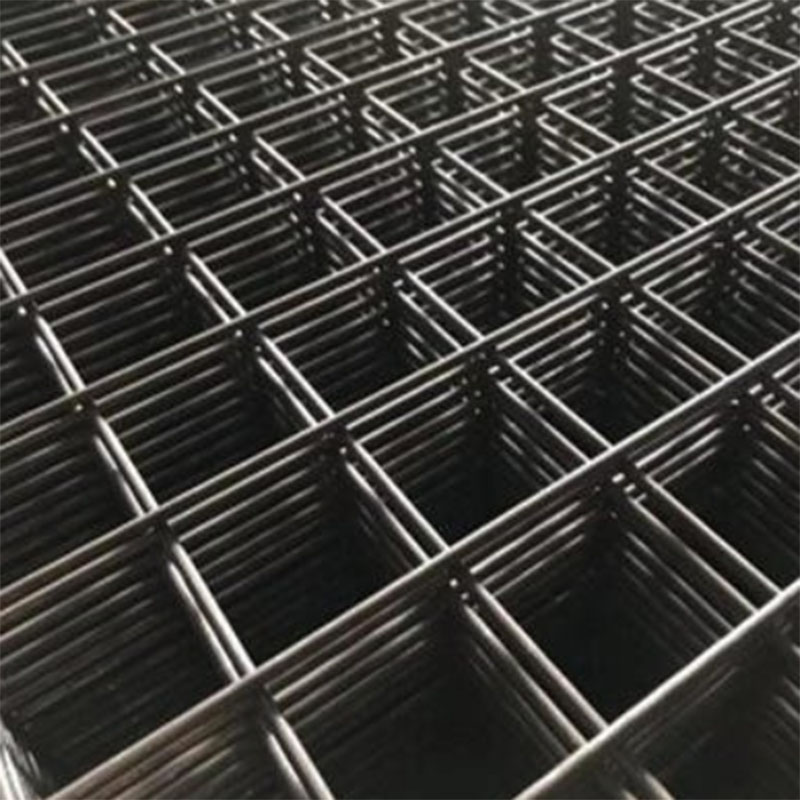

Surface treatment of reinforcing steel mesh:

hot-dip galvanized, electro-galvanized, plastic coated, etc.

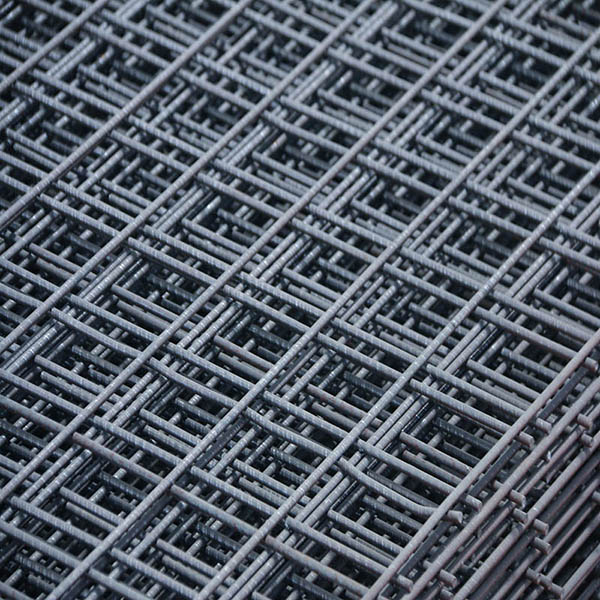

Material selection standard of steel mesh:

The technical specification stipulates that the welded mesh should be made of CRB550 grade cold rolled ribbed steel bar, and can also be made of CRB510 grade cold-drawn smooth steel bar. A piece of welded wire mesh should be welded with the same type of steel bar. Welded wire mesh is classified into two types, fixed type and customized type, according to shape and specification. Customized welded wire mesh can have different spacing and diameters of reinforcement bars in two directions, but the reinforcement bars in the same direction should have the same diameter, spacing and length, which has been stipulated in the relevant standards and regulations. The shape and size of customized welded wire mesh should be determined according to the design and construction requirements, combined with the specific project conditions, by negotiation between the supply and demand sides.

The use of reinforcing steel mesh:

1, to protect the quality of the project, rigidity, good elasticity, high welding strength;

2、Improve seismic and crack resistance, can reduce cracks;

3、Speed up the construction progress, improve the work efficiency, can save working hours;

4, save the amount of steel, alternative to class I steel can save 30% -40% of steel;

5, reduce costs, reduce the cost of the project;

6、Wide range of uses, used in floor slabs, shear walls, bridge decks, mines, pavements, tunnels, holes in the ground, subways, airports.

Since the 20th century, welded steel mesh has been widely adopted by the construction industry as the reinforcement material for concrete structures.

Submitted successfully

We will contact you as soon as possible