Best Selling Stainless Steel Wire Rope

Advantages

1.Hollow grouting anchor strand is twisted from eight strands of spiral ribbed prestressing steel wire, divided into anchoring section and grouting section. The center of anchoring strand is solid steel bar, which can realize resin end anchor; the center of grouting strand is hollow tube, which can be grouted for reinforcement;

2. The end of anchor cable can be used to apply prestressing by anchorage pre-tensioning, and bearing immediately after installation, which is very favorable and necessary for the advantage of loose and soft rock layer and the top rock layer with poor self-stabilizing ability;

3. The steel strand adopts hollow structure, which realizes small diameter and large tonnage of steel strand under the premise of ensuring slurry access; small installation aperture and convenient construction;

4. The steel strand is processed with prestressing spiral ribs, and its anchorage strength and load transfer characteristics are substantially improved compared with that of bare steel strand. Comparative tests show that the anchorage strength of anchor cables made of high strength prestressing spiral rib steel wires with the same diameter of smooth strand is more than doubled when connected to a single anchor cable;

5. Grouting adopts reverse grouting method to ensure that the slurry is full of drilled holes, and the grouting process is simple; and the steel strand meets the requirements of high-pressure grouting, which can realize the combination of anchor and injection.

Product Description:

Hollow grouting anchor cable is suitable for long term support of surrounding rock with medium and good geological conditions, as well as over-head support of highway, railroad, tunnel, slope support, foundation pit support and other projects. Through pressure grouting of the hollow anchor body, it can achieve the purpose of solidifying broken rock body and improving rock body, so as to achieve the purpose of good support. Mining hollow grouting anchor cable is used in coal mines or other mines, shafts and lanes, peripheral rock plus circle, mine lane to the anchor support form and parameters according to the conventional design, often can not be effective support, resulting in the overall collapse of the anchor support, bringing serious consequences. As the length of the steel hinged wire is not restricted, the anchor circle section can be anchored in the hard top plate, at the same time, because of the steel hinged wire strength level is higher, it can provide a larger prestressing force, so that the lower part of the anchor section of the composite top plate joint together as a whole, to form a unified rigid top plate, to play a better support effect.

Technical Parameters

serial number | sports event | SKZ22-1/1770 | SKZ29-1/1670 |

1 | tensile strength(NPa) | 1770 | 1670 |

2 | Nominal diameter of steel stranded wire(mm) | 22 | 29 |

3 | breaking force of an anchor cable(KN) | ≥375 | ≥541 |

4 | lengths(m) | 2.8~15(可按需要加长) | |

5 | elongation(%) | ≥3.5% | ≥3.5% |

6 | Hollow Grouting Pipe Specifications | 内径87.5mm,外径10mm | |

7 | Mounting Hole Diameter(mm) | 30~42 | 38~42 |

8 | Resin anchoring length(mm) | 1000~1500 | |

Grouting anchor cable accessories:

High-pressure grouting pipe, grouting anchor cable strand, special grouting head for grouting anchor cable, slurry stopper, anchor cable grouting valve, mining anchor cable tray, mining anchor cable anchorage, grouting additives; mining anchor cable dynamometer, mining anchor cable tensioning machine, mining anchor cable de-anchorizer, mining anchor cable cutter, and so on.

Hollow Grouting Anchor Cable Composition

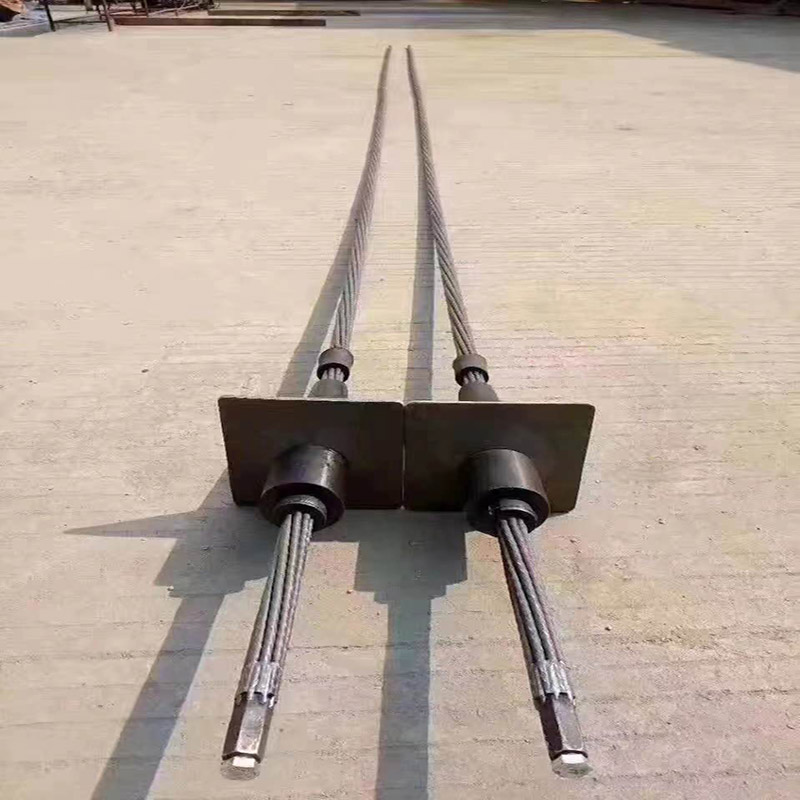

Hollow grouting anchor cable consists of hollow anchor body, anchor head, stopper, pad and nut.

1.Hollow anchor body The anchor body adopts hollow design, the hole in the body is used as a channel for drilling high pressure wind and water and grouting channel, compared with the solid body, the hollow body design can obtain better steel and shear strength. The outer surface of the anchor body is full-length standard large-pitch threaded structure. The threaded structure facilitates cutting and lengthening of the anchor, and increases the bonding area between the anchor body and the grouting material compared with the smooth body, thus improving the anchoring force.

2.Anchor head The anchor head adopts steel anchor head, which can not only fix and center the parts of anchor rod body, but also produce certain anchoring force in the rock anchor hole.

3. Grout stopper The grout stopper is made of rubber-plastic material, considering the grouting exhaust, has certain sealing effect, facilitates the realization of pressurized grouting, and increases the fullness and denseness of the grouting material. Grout stopper has the role of centering bracket.

4. mat plate Adopting hot-rolled molding mat plate, with a certain degree of elasticity, to facilitate the transfer of stress. The pad plate can provide 7 degrees adjustable angle, which is convenient for close adherence to the rock surface.

5. Nut Adopting half-ball or hexagonal nut, active stress can be applied to the rod through the nut.