PC Stranded Wire 12.7mm 15.2mm 12.8mm

PC Stranded Wire

PC stranded conductor is a kind of conductor used for transmission lines, in its name "PC" stands for "Pre-stressed Concrete", that is, prestressed concrete. This kind of conductor is made of prestressed steel wire stranded, with high strength and durability.PC stranded conductor is usually used in long span, large span line or special area transmission project, which can effectively reduce the curvature of the conductor, and improve the stability and transmission capacity of the line.

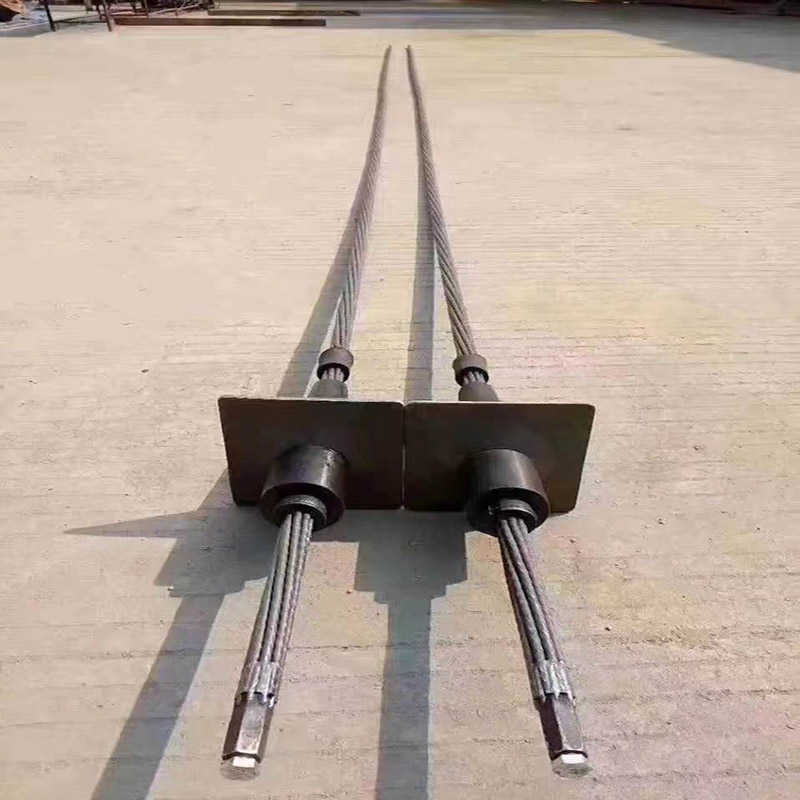

1X3 PC Strand Wire Rope

1X3 PC Strand wire rope is a specially constructed wire rope that is usually used in projects such as hoisting and lifting. This kind of rope consists of a center wire rope with a larger diameter, wrapped with three smaller diameter wire ropes on the outside. This structure allows the rope to strike a balance between load carrying capacity and flexibility, and is suitable for suspending heavy loads and other occasions where high strength is required.

Technical Parameters

serial number | sports event | SKZ22-1/1770 | SKZ29-1/1670 |

1 | tensile strength(NPa) | 1770 | 1670 |

2 | Nominal diameter of steel stranded wire(mm) | 22 | 29 |

3 | breaking force of an anchor cable(KN) | ≥375 | ≥541 |

4 | lengths(m) | 2.8~15(Can be lengthened on request) | |

5 | elongation(%) | ≥3.5% | ≥3.5% |

6 | Hollow Grouting Pipe Specifications | inside diameter87.5mm,external diameter10mm | |

7 | Mounting Hole Diameter(mm) | 30~42 | 38~42 |

8 | Resin anchoring length(mm) | 1000~1500 | |

Product Description:

Hollow grouting anchor cable is suitable for medium geological conditions, good perimeter rock long-lasting support as well as highways, railroads, tunnels, overrun support, slope support, pit support and other projects, through the pressure grouting of the hollow anchor body, it can achieve the consolidation of the broken rock, improve the rock, so as to achieve the purpose of good support.

Hollow grouting anchors can provide higher strength and shear resistance and incomparable bending performance, so that they can better stop or inhibit the inclined movement of rock formation. Anchor ropes are commonly used where the general standard support products are not strong enough or effective.

Mining hollow grouting anchor cable is used in coal mines or other mines, shafts and lanes, peripheral rock plus circle, mine lane to the anchor support form and parameters according to the conventional design, often can not be effective support, resulting in the overall collapse of the anchor support, bringing serious consequences. As the length of the steel hinged wire is not restricted, the anchor circle section can be anchored in the hard top plate, at the same time, because of the steel hinged wire strength level is higher, it can provide a larger prestressing force, so that the lower part of the anchored section of the composite top plate joint together as a whole, to form a unified rigid top plate, to play a better support effect.

Advantages

1.Hollow grouting anchor strand is twisted from eight strands of spiral ribbed prestressing steel wire, divided into anchoring section and grouting section. The center of the anchoring strand is solid steel bar, which can realize resin end anchor; the center of the grouting strand is hollow tube, which can be grouted for reinforcement.

2. The end of anchor cable can be used to apply prestressing by anchorage pre-tensioning, and bearing immediately after installation, which is very favorable and necessary for the advantage of loose and soft rock layer and the top rock layer with poor self-stabilizing ability;

3. The steel strand adopts hollow structure, which realizes small diameter and large tonnage of steel strand under the premise of ensuring slurry access; small installation aperture and convenient construction;

4. The steel strand is processed with prestressing spiral ribs, and its anchorage strength and load transfer characteristics are substantially improved compared with that of bare steel strand. Comparative tests show that the anchorage strength of anchor cables made of high strength prestressing spiral rib steel wires with the same diameter of smooth strand is more than doubled when connected to a single anchor cable;

5. Grouting adopts reverse grouting method to ensure that the slurry is full of drilled holes, and the grouting process is simple; and the steel strand meets the requirements of high-pressure grouting, which can realize the combination of anchor and injection.

Installation of Hollow Grouting Anchor Rope

Before installing the anchor cable to the anchor cable hole, check whether the anchor cable number is the same as the hole number, after confirming that there is no error, then clear the hole once with high pressure wind, then you can start to install the anchor cable.

Installation of downward tilting anchor cable is relatively simple, without more technical problems.

Pay attention to the following four points when installing upward tilting and horizontal anchor ropes:

Check the position of the positioning stop ring and the slurry limiting ring, and replace them according to the technical requirements if they are damaged;

Check the position and smoothness of the exhaust pipe;

When the anchor cable is fed into the hole, stop pushing when the locating slurry stop ring reaches the hole opening, and install the grouting pipe and one-way valve gate;

After the anchor ropes are in place, check again whether the exhaust pipe is smooth, if not, pull out the anchor ropes, and re-feed the ropes after eliminating the problems.

Product Qualification