Split Set Friction Rock Anchor Bolt Mine Tunnel

Advantages and Benefits: Utilizing Split Set Friction Rock Anchor Bolt Mine Tunnel offers several significant advantages, including:

Cost Reduction: The adoption of Equal Strength Split Set Friction Rock Anchor Bolt Mine Tunnel leads to substantial cost savings in support systems, making them an economically advantageous choice for underground coal mines and civil engineering projects.

Enhanced Stability: By providing robust reinforcement, these anchor rods improve stability and reduce the risk of structural failures, ensuring the longevity and reliability of underground engineering projects.

Safety Assurance: The utilization of the threaded anchor rod's secure connection method guarantees the safety of both personnel and assets in underground coal mines, minimizing the potential for accidents and hazards.

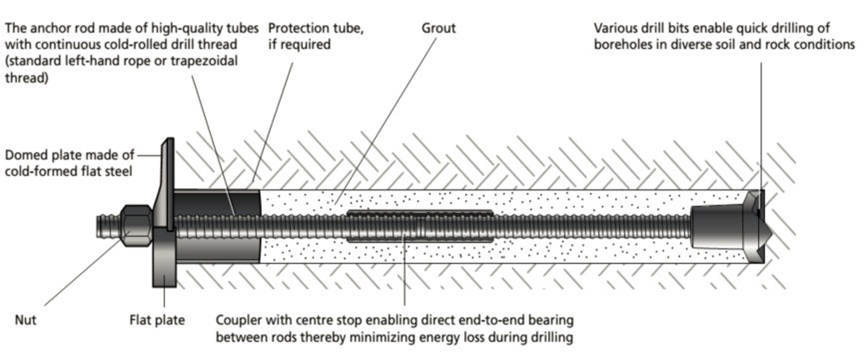

Threaded Rod Concrete Anchors present an invaluable solution for strengthening and stabilizing underground engineering and civil projects. Their high-strength steel construction, smooth threaded surface, and convenient threaded connection design contribute to their reliability, cost-effectiveness, and ease of installation. With their deployment in underground coal mines, they significantly reduce support costs while prioritizing mine safety and stability. By considering Equal Strength Threaded Anchor Rods, underground engineering ventures can be economically feasible while ensuring the well-being of personnel and the overall success of the project.

Split Set Friction Rock Anchor Bolt Mine Tunnel find a multitude of applications in engineering projects. Whether it's tunnel support, slope stabilization, foundation reinforcement, or structural upgrades, these rods cater to various requirements, offering reliable support across different construction endeavors. Installing Split Set Friction Rock Anchor Bolt Mine Tunnel is a streamlined process. The threaded ends facilitate quick and easy connection with other rods or structural components, forming a stable and integrated support system. The efficiency of installation not only saves time but also ensures hassle-free construction.

Technical Parameter | ||||||||

Performance Material Specification | Rod outer diameter(mm) | carrying capacity(kn) | ||||||

Nominal size | Allow partial dragons | HRB335 | HRB400 | HRB500 | HRB600 | HRB335 | ||

standard | carrying capacity | |||||||

φ-16 | 16 | +0.3/-0 | ≧100 | ≧120 | ≧135 | 120x120x5 | ≧100 | |

φ-18 | 18 | +0.3/-0 | ≧126 | ≧150 | ≧172 | ≧206 | 150x150x5 | ≧135 |

φ-20 | 20 | +0.3/-0 | ≧157 | ≧180 | ≧210 | ≧260 | 150x150x6 | ≧170 |

φ-22 | 22 | +0.3/-0 | ≧190 | ≧225 | ≧250 | ≧310 | 150x150x8 | ≧230 |

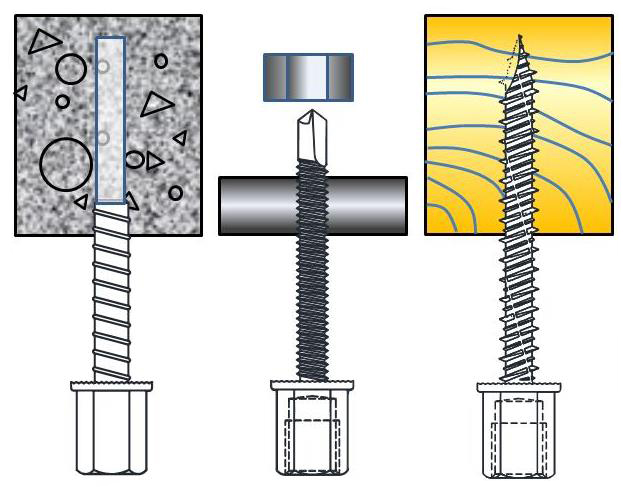

Anchor Characteristics of Split Set Friction Rock Anchor Bolt Mine Tunnel:

1. superficially it restricts the rock and soil body from the original body.

2. Macroscopically it increases the cohesion of the rock and soil body.

3. Anchor rods are not only used in mines, but also used in engineering technology for active reinforcement of slopes, tunnels, dams and so on.

4. Anchor is the basic component of tunnel support in contemporary underground mining, which binds the perimeter rock of the tunnel together, so that the perimeter rock supports itself.

Product Selection and Working Conditions:

Split Set Friction Rock Anchor Bolt Mine Tunnel come in various lengths, diameters, and configurations, allowing for customization to suit specific project requirements. Engineers can tailor the rods to match the unique geological conditions and structural demands of each project.Split Set Friction Rock Anchor Bolt Mine Tunnel play a pivotal role in enhancing structural safety and stability. Their dependable support prevents unwanted structural movement, reducing the risk of potential failures and ensuring the longevity of the entire construction. By minimizing the need for additional reinforcements and expensive construction materials, Threaded Anchor Rods offer a cost-effective solution for engineering projects. Their long-lasting performance significantly reduces maintenance and replacement costs, optimizing the overall project budget. Split Set Friction Rock Anchor Bolt Mine Tunnel are often coated or galvanized to enhance their resistance to corrosion. This protective layer safeguards against environmental factors, ensuring prolonged service life and reliable performance in diverse conditions.

Advantages of Split Set Friction Rock Anchor Bolt Mine Tunnel

1. Anchor end and fastening end do not require machining.

2. Equal strength for the whole length, high material utilization.

3. Large anchorage force.

4. Pre-stressing hot piece is provided, easy to control the installation quality.

5. Fast installation speed.

6. It is made according to the rotating direction of the digging tool, so that the anchor will not exit during the operation.

Split Set Friction Rock Anchor Bolt Mine Tunnel epitomize the essence of secure and versatile structural support. With their robust design, versatile applications, and cost-effective benefits, they serve as a cornerstone of safety and stability in modern construction. From underground tunnels to towering buildings, Split Set Friction Rock Anchor Bolt Mine Tunnel fortify structures, ensuring they stand strong against the test of time. Embrace the strength and reliability of Split Set Friction Rock Anchor Bolt Mine Tunnel, and witness your construction projects reach new heights of success and stability. With Split Set Friction Rock Anchor Bolt Mine Tunnel as the anchor of your vision, you can confidently build a future that embodies unshakable strength and enduring support.

Submitted successfully

We will contact you as soon as possible