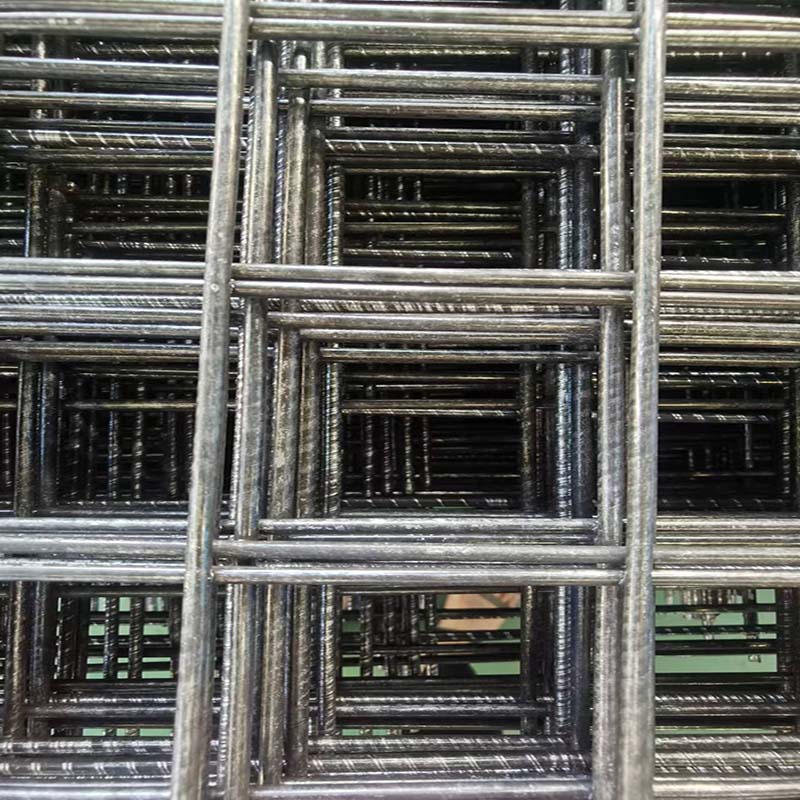

Concrete Steel Wire Mesh

Advantage:

Concrete Steel Wire Mesh offers many advantages, such as Wire Mesh provides support that reinforces the strength and durability of concrete, Concrete Welded Wire effectively prevents cracking and deformation of concrete, and Welded Wire Mesh Panels are easy to install, cost-effective, and have a long service life. These features make Concrete Steel Wire Mesh an ideal choice for construction and roadway projects, providing reliable support and protection.

Product Details:

Concrete Wire Mesh Panels are essential building materials made from sturdy Wire Mesh and Concrete Welded Wire. These panels consist of a series of wires interconnected by welding, creating a reliable and durable structure for various construction applications. The integration of Concrete Steel Wire Mesh in the panels enhances their strength and resistance to cracking and deformation, making them ideal for reinforcing concrete structures and preventing structural failure. With a high level of flexibility and versatility, Concrete Wire Mesh Panels can be easily installed and tailored to fit specific project requirements, providing a cost-effective and efficient solution for builders and contractors. Whether used in constructing walls, floors, or other structural elements, these panels ensure the integrity and longevity of the concrete structure, offering maximum support and protection in all construction projects.

General Specifications:

Parameters of reinforced mesh | |||

Mesh Size | Wire Diameter | Panel Sizes | |

In Inch | In MM | In MM | Common sizes: 2.2 x 5.8m, 2.0 x 2.9m

Other sizes can be made as request |

2” x 4” | 50 x 100mm | 4.0mm – 10.0mm | |

3” x 4” | 75 x 100mm | 4.0mm – 10.0mm | |

4” x 4” | 100 x 100mm | 4.0mm – 12.0mm | |

6” x 6” | 150 x 150mm | 4.0mm – 12.0mm | |

8” x 8” | 200 x 200mm | 4.0mm – 12.0mm | |

Advantage:

Firmly welded, even mesh holes, flat mesh surface, corrosion resistance, high strength, strong protective ability.

Welded Mesh Overview:

Mining welded wire mesh is made of low carbon steel wire spot welded, mesh size, wire diameter thickness can be changed, in the mine, shaft, mine tunnels can play a certain role in supporting, welded wire mesh is strong and durable, long life.

There are many kinds of steel mesh for coal mine, which are divided into four kinds of crimped woven welded steel mesh positioning woven welded welded steel mesh straight wire woven steel mesh and flat welded steel mesh. They are all made of cold-drawn low carbon steel wire, featuring smooth weaving, even mesh, reasonable structure, firm welding joints and so on. It has good corrosion resistance and is mainly used for coal mine support and mine safety protection. It can also be used in high-rise commercial buildings, airports and runways, highways, tunnels, bridges, concrete pipelines, docks, warehouses, sewage treatment and other reinforced concrete structures.

It can also be used in high-rise commercial buildings, airports, tunnels, highways, bridges, concrete pipelines, docks, warehouses, sewage treatment and other reinforced concrete structures. Mining braided welded steel mesh is now a new type of coal mine support mesh, which is characterized by first braided and then welded, beautiful and durable structure, strong tensile strength, corrosion-resistant, easy to install and easy to construct.

Coal mine support mesh use:

The mesh is used for coal mine roof protection, tunnel, bridge construction, roadbed mesh reinforcement, building materials for construction sites.

Mesh Type:

Mesh can be divided into welded wire mesh woven wire mesh, galvanized wire mesh and dip-plasticized wire mesh, welded wire mesh is most commonly used.

Classified by material:

stainless steel mesh, black iron wire mesh.