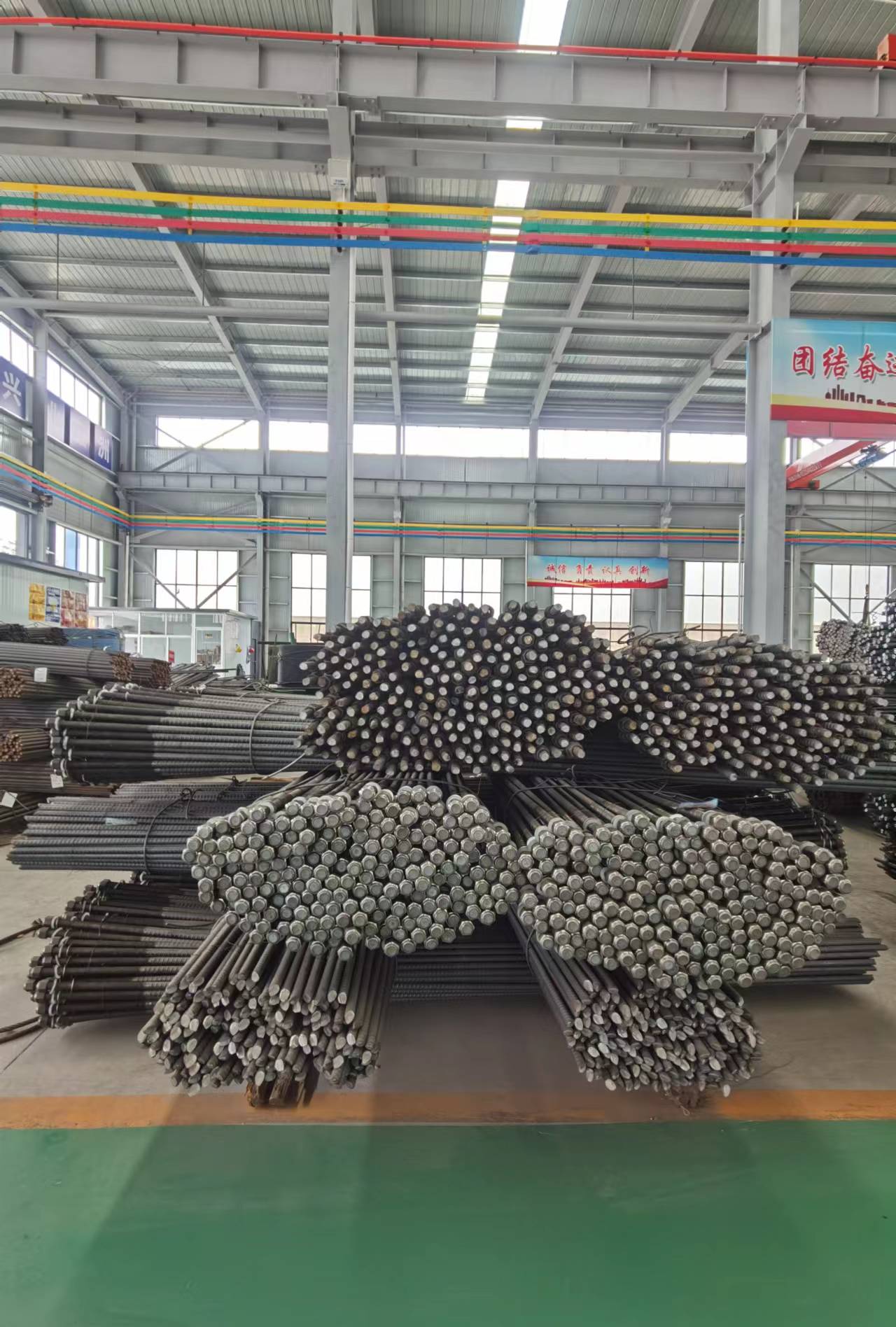

Longitudinal Ribless Threaded Rod Anchoring

Longitudinal ribless rebar resin anchors are primarily utilized for providing strong support to roadways with significant deformation in high-pressure mines. These roadways can include full rocky roadways, coal roadways, and semi-coal roadways. Additionally, these anchors can also be employed for ensuring high-strength and long-lasting support to railroads, highways, hydropower projects, and other similar endeavors.

Threaded anchor without longitudinal rib is a special rod used for strengthening and stabilizing underground engineering or civil engineering. It is made of high-strength steel and has a threaded surface without longitudinal ribbing. The threaded anchor rod without longitudinal rib adopts threaded connection method, which can be easily connected with other rods or structural parts to form a stable support system.

Longitudinal Ribless Threaded Rod Anchoringcan be extended in length through threaded connection to meet different engineering needs. This anchor rod has high tensile, shear and torsional strength, which can provide reliable support and fixation. It is widely used in tunnels, underground mines, water conservancy projects, transportation and other fields to strengthen rock, soil or concrete structures. The advantages of threaded anchors without longitudinal ribs include easy installation, light weight, reusability, and short construction period. Longitudinal Ribless Threaded Rod Anchoring can improve engineering construction efficiency, reduce engineering cost, and has a long service life. All in all, threaded anchor without longitudinal rib is an important engineering support material, which can provide strong and reliable support, and is widely used in various underground engineering and civil engineering.

Technical Parameter | ||||||||

Performance Material Specification | Rod outer diameter(mm) | carrying capacity(kn) | ||||||

Nominal size | Allow partial dragons | HRB335 | HRB400 | HRB500 | HRB600 | HRB335 | ||

standard | carrying capacity | |||||||

φ-16 | 16 | +0.3/-0 | ≧100 | ≧120 | ≧135 | 120x120x5 | ≧100 | |

φ-18 | 18 | +0.3/-0 | ≧126 | ≧150 | ≧172 | ≧206 | 150x150x5 | ≧135 |

φ-20 | 20 | +0.3/-0 | ≧157 | ≧180 | ≧210 | ≧260 | 150x150x6 | ≧170 |

φ-22 | 22 | +0.3/-0 | ≧190 | ≧225 | ≧250 | ≧310 | 150x150x8 | ≧230 |

Anchor Characteristics:

1. superficially it restricts the rock and soil body from the original body.

2. Macroscopically it increases the cohesion of the rock and soil body.

3. Anchor rods are not only used in mines, but also used in engineering technology for active reinforcement of slopes, tunnels, dams and so on.

4. Anchor is the basic component of tunnel support in contemporary underground mining, which binds the perimeter rock of the tunnel together, so that the perimeter rock supports itself.

Product Selection and Working Conditions:

1. Product selection: support designers according to the roadway section of the surrounding rock geological conditions to detect the surrounding rock to pressure parameters, and then combined with practical experience, can choose different specifications of the anchor.

2. Using working conditions: Users should have drilling and installation equipment, resin anchors and so on. In order to increase the effect of support, after the installation of anchor rods, plus the installation of anchor net anchor cable and slurry. The drilling size and depth should be used according to the specifications of anchor rods and anchoring agents; considering the power conditions of the site, it is recommended to prioritize the use of pneumatic anchor drilling rigs or hydraulic anchor drilling rigs so that the drilling and installation are carried out in the same machine: for the use of high rock hardness site selection of the 7655 wind hammer drilling, pneumatic coal drilling and stirring installation. Stirring installation of rated output speed ≥ 400 rpm output torque, for the full-length anchoring should be 2 60Nm; for end anchoring should be 240Nm machine.

Advantages

1. Anchor end and fastening end do not require machining.

2. Equal strength for the whole length, high material utilization.

3. Large anchorage force.

4. Pre-stressing hot piece is provided, easy to control the installation quality.

5. Fast installation speed.

6. It is made according to the rotating direction of the digging tool, so that the anchor will not exit during the operation.