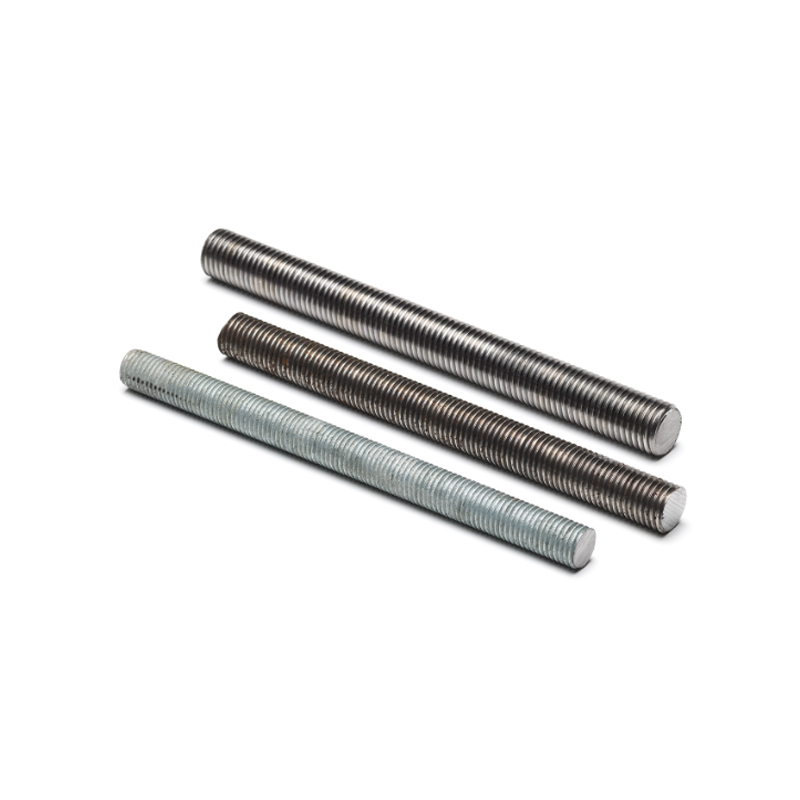

Mine Support Full Thread Bar Resin Rock Bolt

Equal Strength Threaded Anchor Rod :Strengthened with identical electricity rebar and geared up with a resin anchor, those metallic rod body merchandise locate huge utility in supporting underground rocky tunnels, semi-coal rocky tunnels, and coal tunnels. they may be specially properly-proper for presenting reliable resource in tough underground situations and bunker environments.

Unleashing Exceptional Support and Strength - Equal Strength Threaded Anchor Rod

An Unparalleled Support Tool in Underground Engineering

Introduction: Underground engineering has always been a realm of human exploration, and an efficient and reliable support system is crucial for the safety of underground tunnels and mines. To fulfill this assignment, we are proud to introduce the same energy threaded anchor rod, a product that provides remarkable aid and electricity for underground tasks.

The product boasts several fantastic characteristics when used with resin anchors:

Rapid strength development: With quick strength growth, it exhibits high load-bearing capacity immediately after installation, providing robust anchoring force.

Easy installation and operation: Its user-friendly design ensures simple and efficient installation, reducing the labor intensity for workers while enhancing support efficiency.

Cost-effective coal support: The implementation of this product results in significant cost reduction for coal support.

Compliant with MT164.2-2011 standards: The product adheres to the necessities set forth in mt164.2-2011, making sure its reliability and conformity to enterprise guidelines.

Outstanding Performance: The Equal Strength Threaded Anchor Rod is a threaded anchor rod product based on equal-strength reinforced steel. It is widely used in supporting underground rocky tunnels, semi-coal rocky tunnels, and coal mine tunnels. Moreover, this product excels in supporting projects under complex underground conditions and covert engineering.

Equal Strength Threaded Anchor Rod | Material | HRB335 HRB400 HRB500 |

standard(mm) | φ16 φ18 φ20 φ22 length:Depending on design requirements |

Instant Powerful Support: When used in conjunction with resin anchor agents, the Equal Strength Threaded Anchor Rod stands out with its rapid strength development. After installation, it can bear loads promptly and provide substantial anchoring force, injecting powerful support into underground engineering.

Simple and green set up: we're dedicated to making the product person-friendly and efficient. the set up and operation of the same power threaded anchor rod are truthful, extensively reducing labor intensity for employees and increasing help efficiency. with minimal effort, you can effortlessly whole the installation, making sure the assist device is quick operational.

Material | 20MnSi | ||||

Strength Specification | Yield Load(MPa) | Tensile Strength(MPa) | Extensibility(%) | Breakage load(KN/M) | Theoretical quality(KG/M)

|

φ16 | ≧335 | ≧490 | ≧16 | ≧100 | 1.6

|

φ18 | ≧335 | ≧490 | ≧16 | ≧126 | 2.0

|

Φ20 | ≧335 | ≧490 | ≧16 | ≧156 | 2.5

|

Φ22 | ≧335 | ≧490 | ≧16 | ≧189 | 3.0 |

Reducing Coal Mine Support Costs:Help in underground coal mines is critical for safe production. the utilization of the equal energy threaded anchor rod significantly reduces support expenses, presenting you with an economically possible coal mine support answer whilst making sure the steadiness and protection of the mine and its personnel.

Compliance with Standards:The improvement of the equal strength threaded anchor rod is based totally on the mt164.2-2011 widespread, ensuring the product's reliability and adherence to industry guidelines. you could use it with self assurance, without worrying approximately product fine issues.

Conclusion: The Equal Strength Threaded Anchor Rod is a star product in underground engineering, possessing robust support and strength, providing an efficient and reliable solution for supporting underground tunnels and mines. We firmly believe it will become your powerful ally in underground projects, safeguarding your endeavors. Let us work together to create a brighter future for underground engineering!