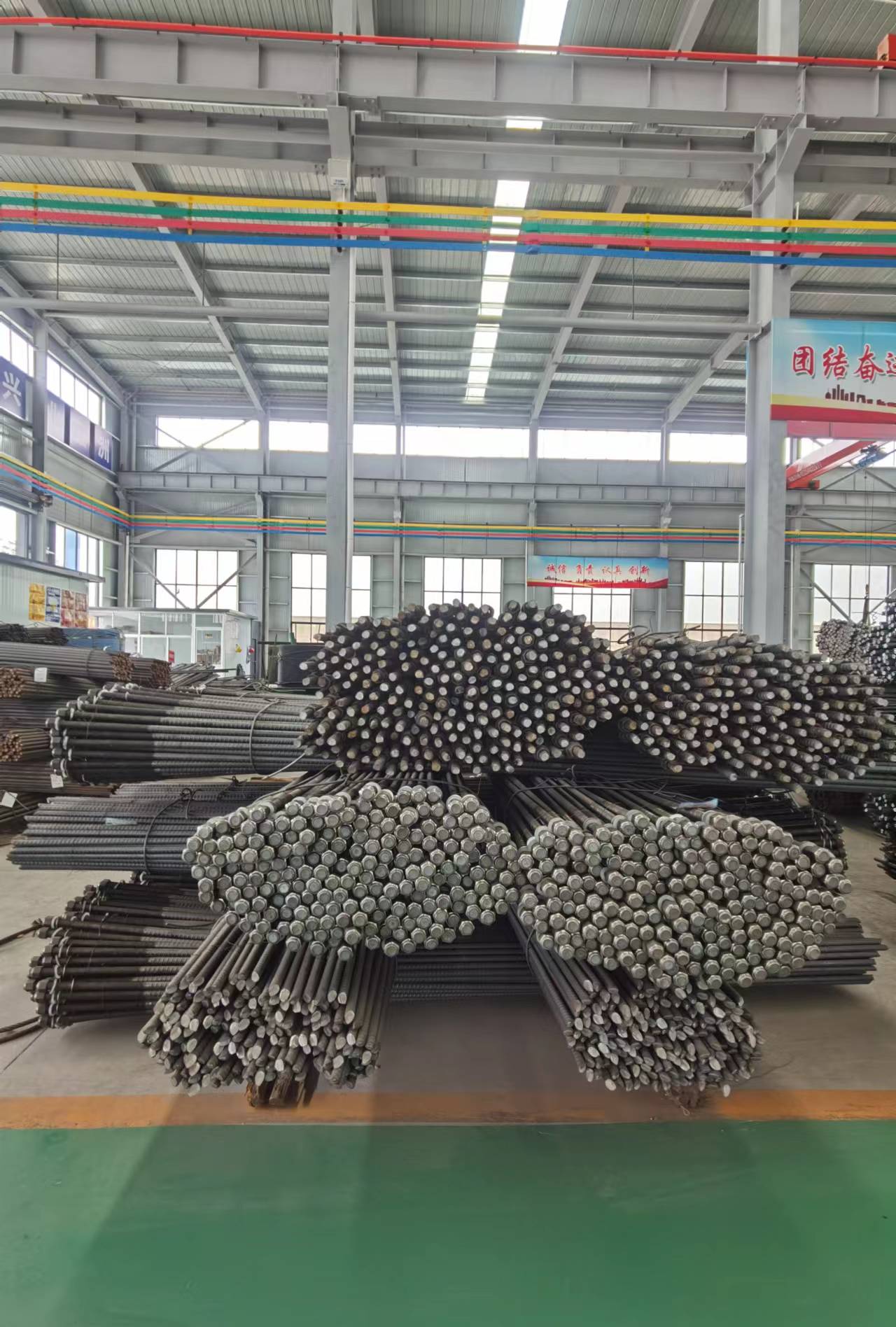

Threaded Rod Anchor Horizontal 1 4

Within the realm of creation, wherein goals take shape and visions come to be truth, one element stands as the cornerstone of success: balance. introducing threaded anchor rods, the unsung heroes that embody energy, adaptability, and engineering precision to anchor the foundations of fantastic structures.

Threaded anchor rods are a symphony of precision engineering, each thread meticulously crafted to interlock seamlessly with materials. this symmetrical design ensures a comfy healthy, creating a strong and unyielding connection that fortifies systems against external pressures and the ravages of time.

Longitudinal ribless threaded rod anchoringcan be prolonged in length thru threaded connection to meet distinct engineering goals. this anchor rod has excessive tensile, shear and torsional power, which can offer reliable assist and fixation. it's far widely applied in tunnels, underground mines, water conservancy projects, transportation and unique fields to enhance rock, soil or concrete systems. the benefits of threaded anchors without longitudinal ribs encompass easy installation, slight weight, reusability, and brief creation length.longitudinal ribless threaded rod anchoring can improve engineering creation efficiency, reduce engineering price, and has an extended service life. all in all, threaded anchor with out longitudinal rib is an important engineering aid cloth, that may provide sturdy and dependable support, and is widely utilized in numerous underground engineering and civil engineering.

Technical Parameter | ||||||||

Performance Material Specification | Rod outer diameter(mm) | carrying capacity(kn) | ||||||

Nominal size | Allow partial dragons | HRB335 | HRB400 | HRB500 | HRB600 | HRB335 | ||

standard | carrying capacity | |||||||

φ-16 | 16 | +0.3/-0 | ≧100 | ≧120 | ≧135 | 120x120x5 | ≧100 | |

φ-18 | 18 | +0.3/-0 | ≧126 | ≧150 | ≧172 | ≧206 | 150x150x5 | ≧135 |

φ-20 | 20 | +0.3/-0 | ≧157 | ≧180 | ≧210 | ≧260 | 150x150x6 | ≧170 |

φ-22 | 22 | +0.3/-0 | ≧190 | ≧225 | ≧250 | ≧310 | 150x150x8 | ≧230 |

Anchor Characteristics:

1. superficially it restricts the rock and soil frame from the authentic body.

2. macroscopically it's going to boom the concord of the rock and soil frame.

3. anchor rods are not nice used in mines, but considerably utilized in engineering technology for active reinforcement of slopes, tunnels, dams and so forth.

4. anchor is the simple element of tunnel help in modern underground mining, which binds the perimeter rock of the tunnel together, in order that the fringe rock supports itself.

Product Selection and Working Conditions:

1. product choice: assist designers consistent with the roadway segment of the surrounding rock geological conditions to come across the surrounding rock to pressure parameters, and then blended with sensible revel in, can select distinctive specifications of the anchor.

2. Using running conditions: users should have drilling and set up device, resin anchors and so on. for you to growth the effect of guide, after the installation of anchor rods, plus the set up of anchor internet anchor cable and slurry. the drilling size and depth should be used consistent with the specs of anchor rods and anchoring marketers; considering the strength conditions of the net page, it's miles encouraged to prioritize the use of pneumatic anchor drilling rigs or hydraulic anchor drilling rigs just so the drilling and set up are executed inside the identical machine: for the usage of immoderate rock hardness internet page selection of the 7655 wind hammer drilling, pneumatic coal drilling and stirring set up. stirring installation of rated output velocity ≥ four hundred rpm output torque, for the overall-duration anchoring must be 2 60nm; for give up anchoring need to be 240nm device.

Advantages

1. Anchor end and fastening end do not require machining.

2. Equal strength for the whole length, high material utilization.

3. Large anchorage force.

4. pre-stressing hot piece is furnished, smooth to manipulate the installation best.

5. fast set up velocity.

6. it's miles made in step with the rotating course of the digging device, so that the anchor will not exit during the operation.