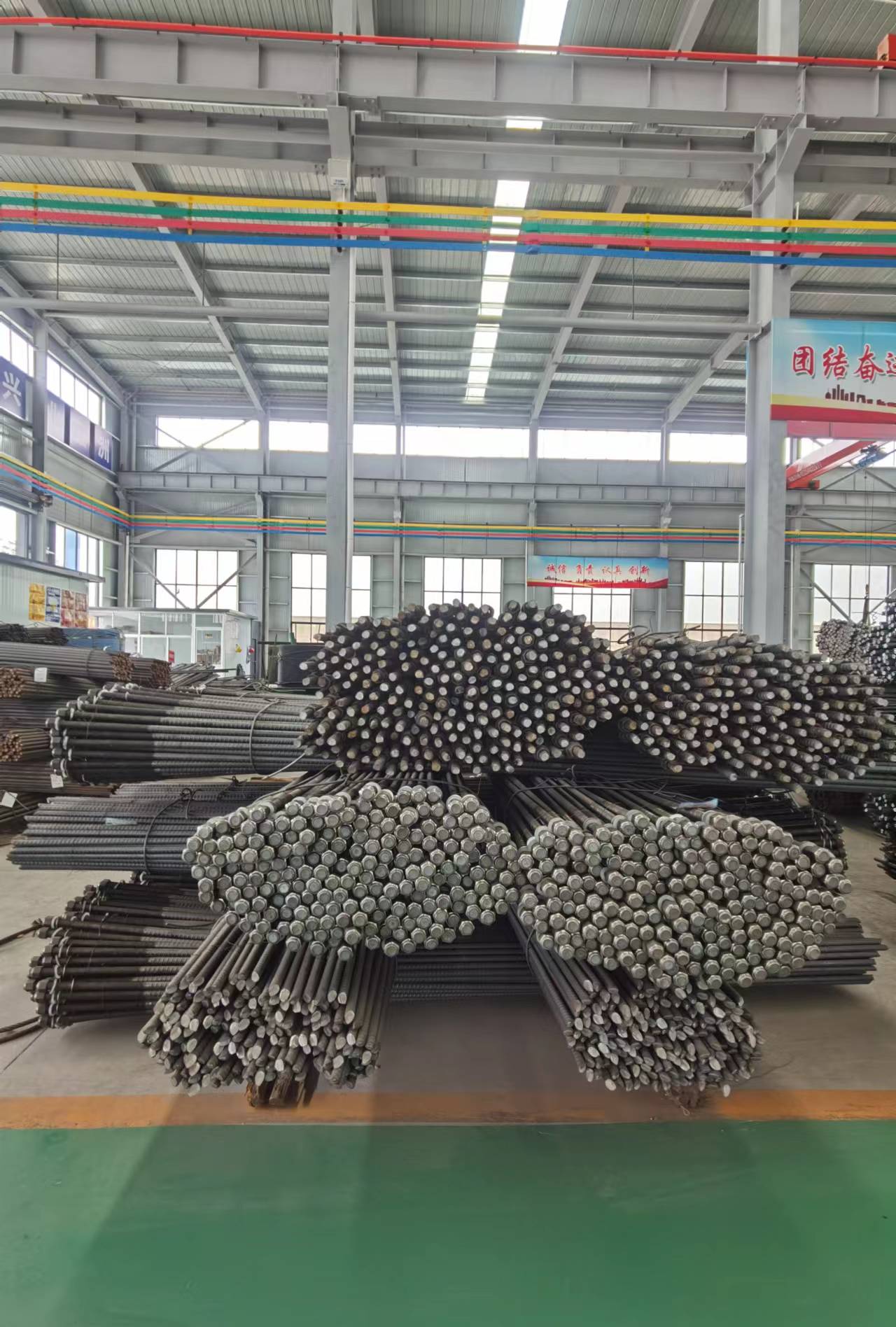

Threaded Rods Concrete Anchors

Longitudinal Ribless Rebar Resin Anchors excel in offering robust support to roadways facing substantial deformation in high-pressure mining environments. Those roadways embody complete rocky, coal, and semi-coal systems. moreover, these anchors are equally effective in imparting excessive-electricity, enduring support to railways, highways, hydropower projects, and comparable undertakings.

The threaded anchor without longitudinal rib is a specialised rod designed to reinforce and stabilize underground engineering and civil initiatives. created from high-strength steel, this anchor functions a clean threaded surface with out longitudinal ribbing. its threaded connection approach lets in for clean integration with different rods or structural components, forming a robust and stable guide device.

The Threaded Anchor without Longitudinal Rib is a unique and high-strength steel rod specifically engineered to enhance the stability and fortification of underground and civil engineering projects.With its clean threaded surface and shortage of longitudinal ribbing, this anchor gives seamless integration and smooth reference to other rods or structural elements, forming a reliable and at ease guide system. its versatility and reliability make it an critical thing for boosting diverse production ventures.

Technical Parameter | ||||||||

Performance Material Specification | Rod outer diameter(mm) | carrying capacity(kn) | ||||||

Nominal size | Allow partial dragons | HRB335 | HRB400 | HRB500 | HRB600 | HRB335 | ||

standard | carrying capacity | |||||||

φ-16 | 16 | +0.3/-0 | ≧100 | ≧120 | ≧135 | 120x120x5 | ≧100 | |

φ-18 | 18 | +0.3/-0 | ≧126 | ≧150 | ≧172 | ≧206 | 150x150x5 | ≧135 |

φ-20 | 20 | +0.3/-0 | ≧157 | ≧180 | ≧210 | ≧260 | 150x150x6 | ≧170 |

φ-22 | 22 | +0.3/-0 | ≧190 | ≧225 | ≧250 | ≧310 | 150x150x8 | ≧230 |

Anchor Characteristics:

Superficially, it confines the rock and soil frame, limiting its enlargement from the unique kingdom.

On a macroscopic level, it enhances the cohesion of the rock and soil body, promoting structural integrity.

Anchor rods find versatile applications beyond mining, extending to engineering technologies that actively reinforce slopes, tunnels, dams, and other projects.

Anchors serve as fundamental components in contemporary underground mining tunnel support, efficaciously bonding the fringe rock of the tunnel, allowing self-assist of the encompassing rock shape.

Product Selection and Working Conditions:

Product Selection: Support designers will assess the geological conditions of the encircling rock and determine the strain parameters to pick the right anchor specifications.This decision-making process incorporates practical experience to ensure an optimal choice. Utilizing Working Conditions: Users must possess drilling and installation equipment, as well as resin anchors, among other essentials. To enhance support effectiveness, after installing anchor rods, complement the setup with anchor nets, anchor cables, and slurry. The drilling size and depth need to align with the specs of anchor rods and anchoring sellers. considering website electricity competencies, it's miles beneficial to prioritize pneumatic or hydraulic anchor drilling rigs that facilitate drilling and installation in a single operation. for websites with excessive rock hardness, choose the 7655 wind hammer drilling, pneumatic coal drilling, and stirring installation. stirring set up necessitates a rated output speed of ≥ four hundred rpm and an output torque of 260nm for complete-length anchoring and 240nm for cease anchoring.

Advantages

1. Anchor end and fastening end do not require machining.

2. Equal power for the whole length, excessive fabric utilization.

3. Big anchorage pressure.

4. Pre-stressing hot piece is provided, smooth to manipulate the installation first-class.

5. Fast installation speed.

6. It is made according to the rotating direction of the digging tool, so that the anchor will not exit during the operation.