Top Suppliers Of Rebar φ22 φ20 φ18

Product Advantages

1. Anchor end and fastening end do not require machining.

2. Equal strength for the whole length, high material utilization.

3. Large anchorage force.

4. Pre-stressing hot piece is provided, easy to control the installation quality.

5. Fast installation speed.

6.It is made according to the rotating direction of the digging tool, so that the anchor will not exit during the operation.

Product Overview

The longitudinal ribless threaded steel resin anchor executes MT146.2-2011 standard. It is a kind of anchor made by special processing technology, the strength of threaded section is greater than the strength of the rod body, the threaded section has good performance of bending and shearing, it is a new type of anchor for high strength support of shaft.

The anchor has high strength, reasonable structure, large tightening force, can automatically adjust the direction of force, increase the binding force on the rock can realize the mechanization of rapid installation. It can be used as end anchor, extension anchor and full anchor, and is mainly used for high strength support of large deformation roadway in highland pressure mines. Application:Coal mine roadway support, but also can be used for railroads, hydropower and other types of engineering high-strength permanent roadway support.

Product Parameters

Technical Parameters | ||||||||

Performance Material Specification | Rod outer diameter (mm) | carrying capacity(kn) | ||||||

Nominal size | tolerance | HRB335 | HRB400 | HRB500 | HRB600 | HRB335 | ||

norm | carrying capacity | |||||||

φ-16 | 16 | +0.3/-0 | ≧100 | ≧120 | ≧135 | 120x120x5 | ≧100 | |

φ-18 | 18 | +0.3/-0 | ≧126 | ≧150 | ≧172 | ≧206 | 150x150x5 | ≧135 |

φ-20 | 20 | +0.3/-0 | ≧157 | ≧180 | ≧210 | ≧260 | 150x150x6 | ≧170 |

φ-22 | 22 | +0.3/-0 | ≧190 | ≧225 | ≧250 | ≧310 | 150x150x8 | ≧230 |

Anchor characteristics:

1. superficially it restricts the rock and soil body from the original body.

2. Macroscopically it increases the cohesion of the rock and soil body.

3. Anchor rods are not only used in mines, but also used in engineering

4. Anchor is the basic component of tunnel support in contemporary underground mining, which binds the perimeter rock of the tunnel together, so that the perimeter rock supports itself.

Product Features

This product is a kind of anchor made by special processing technology, the strength of the threaded section is greater than the strength of the rod body, and the bending and shear resistance is good, it is a new type of anchor for high strength support in shafts. It is a new type of anchor for high strength support of shafts. It has reasonable structure, large preload, can automatically adjust the direction of force, increase the binding force on the surrounding rock, and can be mechanized and installed quickly, and can be used as end anchors, extension anchors and full anchors. It is easy to transport, anti-corrosion and anti-rust, and has a wide range of applications.

Structural features and working principle

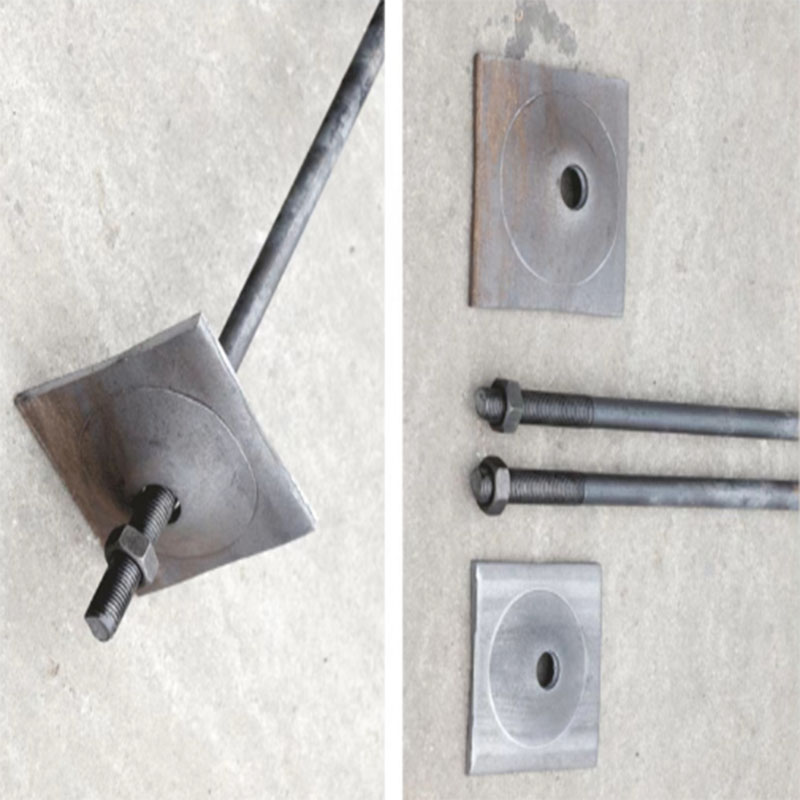

1, structural features: each set of non-longitudinal aid threaded steel type resin anchor by the metal rod body (rod end of a section of 80 ~ 120mm thread) with a thickened hexagonal nut, an anchor tray.

2, working principle: anchor is anchored in the rock body to maintain the stability of the surrounding rock rod-like structure, in the surrounding rock to play the role of suspension, combination of beams, combination of arches, wedge and so on. In the installation process, the resin anchor metal rod body plays the role of mixer, the rod body through the anchor drilling rig rotation into the hole has been punched, will be placed in advance of the hole end of the resin anchoring agent pounding broken, so that the resin cement and curing agent mixed with a chemical reaction, the resin cement is quickly cured, the rock and the anchor rod bonded together, to play the role of anchoring. A certain number of anchors are driven in the same piece of surrounding rock to form an anchor support system.

Usage:

1. Determine the anchor hole position according to the design requirements and drill the hole with drilling rig.

2. Use the pressurized air pipe to go deep into the bottom of the hole and blow clean the rock dust.

3. Send the anchoring agent into the bottom of the hole, set it with the anchor to start mixing (mixing time is specified according to the model of the anchoring agent), mixing is finished, unload the mixing apparatus to reach the waiting cooling time, unload the mixing connecting head to install the anchor plate, ball washer friction washer, and tighten the nut with a special wrench.