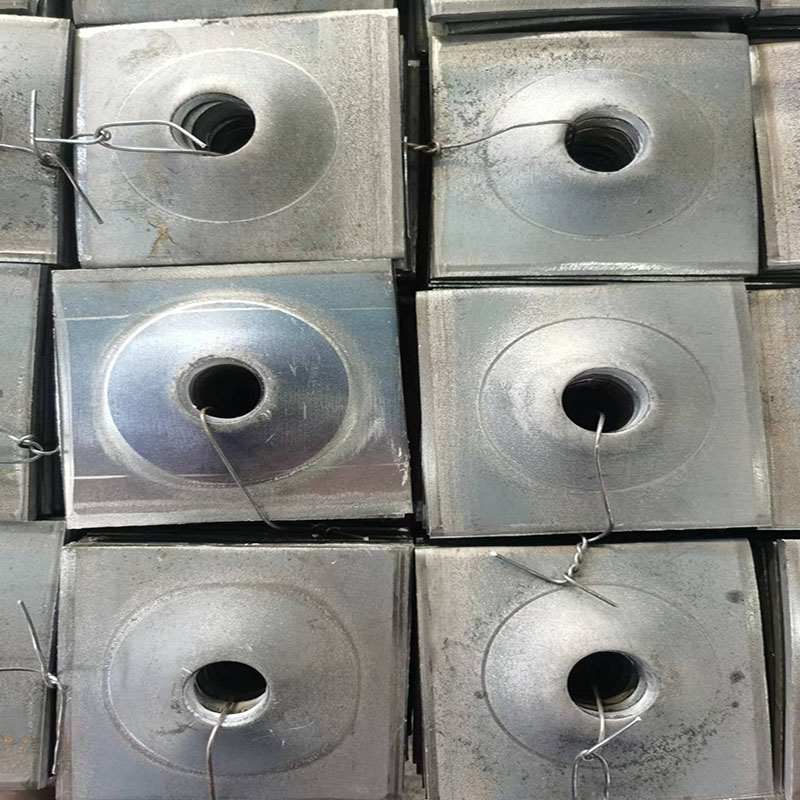

Perforated Metal Sheet Supplier 200*200*10

The product advantages of anchor pallets and anchor cable pallets mainly include the following points:

1. Excellent material: made of alloy plate, it has high strength and durability and can withstand large force effect.

2. Unique design: The special shape design helps to enhance the force effect and improve the stability and effect of the support system.

3. Lightweight and easy to install: the product is lightweight and easy to carry and install, which not only saves time and labor cost, but also reduces the construction difficulty.

4. Good compatibility: it can be used perfectly with all kinds of anchor rods and anchor cables to improve the surface control effect of the overall support system.

Taken together, the advantages of these products lie in high material strength, unique design, easy installation and good compatibility, which can effectively improve the performance of the support system and guarantee the quality of the project.

Product Details:

Anchor disk is an important part of mine support, which is mainly divided into two types: square round hole anchor disk and round round hole anchor disk. They are fixed inside the surrounding rock by anchors to change the mechanical state of the surrounding rock and form a stable rock belt, which maintains the stability of the roadway through the joint action of anchors and surrounding rock.

In mine support, anchor pan is an active defensive support method, representing a major change in the field of mine support. Through the application of anchor disk, the surrounding rock can be effectively reinforced to prevent the occurrence of geologic disasters and ensure the working environment and operational safety.

The square round hole anchor disk and round round hole anchor disk have their own characteristics and applicable scenes, the specific selection should be based on the project needs and the surrounding rock conditions to make a reasonable design and layout. As a key component of anchor support system, anchor disk has wide application and important significance in the field of mine and tunnel engineering.

Specifications and parameters:

Pallet Size(mm) | carrying capacity (kn) (kn) | Pallet Size(mm) | carrying capacity(kn) | note |

120x120x5 | ≧100 | 200x200x10 | ≧360 | Partial specifications |

120x120x6 | ≧115 | 200x200×12 | ≧420 | |

120x120x8 | ≧130 | 250x250×8 | ≧320 | |

150x150×5 | ≧135 | 250x250x10 | ≧400 | |

150x150x6 | ≧170 | 250×250x12 | ≧440 | |

150x150x8 | ≧230 | 300x300x10 | ≧420 | |

150x150x10 | ≧290 | 300x300x12 | ≧480 | |

120x120x10 | ≧260 | 300x300x14 | ≧520 |

Product Description:

Anchor disk is one of the important materials in the mine support system, which is used to cooperate with anchor rods for support work. The main function of the anchor plate is to be fixed inside the rock body through close contact with the rock body, together with the anchor rods, in order to reinforce and stabilize the surrounding rock, and ensure the safety and stability of the workplace.

Anchor disk has various shapes, and the common ones are round, square and diamond. Different shapes of anchor plates can be selected and matched according to the support needs and characteristics of the surrounding rock in order to achieve the best support effect.

Overall, as an important part of the mine support system, the anchor plate plays a key role in effectively maintaining the stability and safety of mines and tunnels through the use of anchor rods.

The steps for using an anchor disk with an anchor metal rod and nut to form a set of anchors are as follows:

1. Determine the anchor hole position according to the design requirements, and use the drilling rig to drill the hole position.

2. Use pressurized air equipment to blow clean the rock dust inside the hole to ensure that the inside of the hole is clean.

3. Ensure that the diameter of the rock hole is 6-12mm larger than the diameter of the anchor rod in order to lay the anchor rod.

4. Inject the anchoring agent into the bottom hole, turn on the mixing device for mixing, and strictly control the mixing time according to the requirement of resin anchoring agent to ensure the curing effect.

5. Wait for the end of the curing time, put the anchor disk on the anchor rod and tighten the nut to ensure that the anchor disk and the anchor rod are firmly connected.