Quality Mining Resin Anchoring Agent

Product Benefits

Simple operation,

large anchoring force,

good resistance,

good seepage resistance,

short setting time,

easy to transport.

Description of resin anchors

Resin anchoring agent is made of unsaturated polyester resin, curing agent, accelerator and other auxiliary materials, according to a certain proportion of the viscous form of anchoring bonding material, by the polyester film divided into packages in the form of medicine rolls, with fast curing at room temperature, high adhesive strength, reliable anchoring force and durability and other excellent performance.

Resin anchor parameters

Diameter: ¢21mm, 423mm, ¢28mm, c32mm, ¢35mm, ¢42mm, ¢70mm.

Length: 300mm, 330mm, 350mm, 450mm, 500mm, 600mm, 660mm, 750mm, 880mm and so on, and can also be customized according to user requirements.

Product Features

1, bearing fast, anchoring performance is similar to steel embedded parts. It has the characteristics of "double fast and high", i.e. fast curing time (adjustable speed), fast strength growth and high strength. After installation

Only in time to withstand the load, and anchoring force.

2, Resin anchoring agent adaptability, bonding object wide. Adhesive shaped, complex large sheet structure, can anchor a variety of wood, metal, fiberglass body and other rigid objects.

Objects.

3, has good fatigue strength. Lipid anchors can be widely used for structural reinforcement, rock support, equipment foundation fixing, dam crack repair and high-rise building exterior stone

Dry hanging, installation and fixing of metal or curtain wall frames, etc.

4, water-resistant resin anchoring agent in addition to the above characteristics, when there is water present, has the characteristics of fast enhancement, high strength, to avoid the impact of water on the resin anchoring agent curing rate, compressive strength and anchoring force.

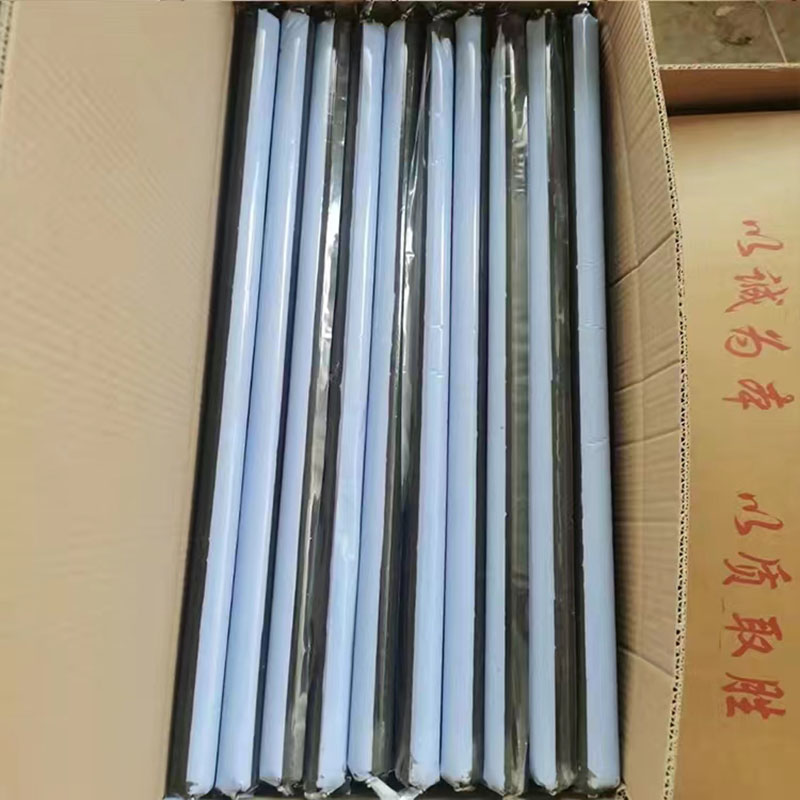

Anchor anchoring agent packaging, storage

This agent is packed in 25kg carton box with plastic bag inside for protection. Transportation and storage should be prevented from breakage and moisture. The unused rolls should be wrapped tightly and should not be exposed to moisture, with a storage period of 6 months.