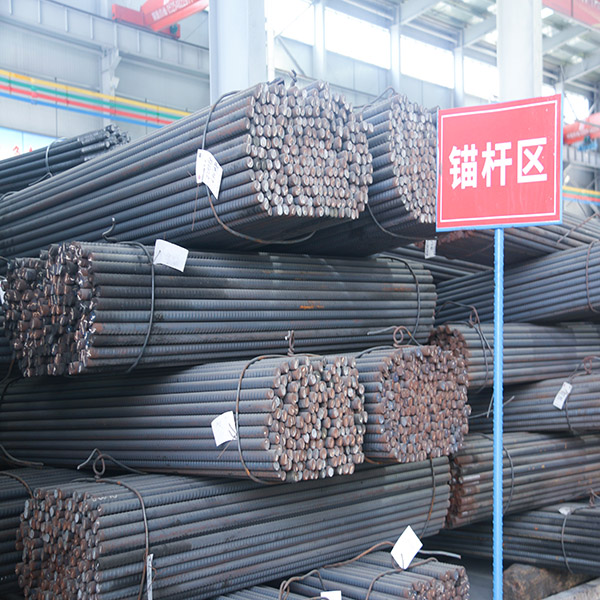

Equal Strength Threaded Anchor Rod

(1)reasonable and simple structure, it's far the replacement made from anti-twist anchors

(2)anchor full thread identical energy, than the equal specs of anti-twist anchor bearing capability

Growth 40%.

(3)expanding the use variety of anchor, can recognise end anchor and full anchor.

(4)low charge, extensively used in coal mines, railroads, hydropower and other styles of engineering roadway help.

Product usage and characteristics of Equal Strength Threaded Anchor Rod

Same electricity rebar kind resin anchor metal rod frame merchandise are widely utilized in underground rocky tunnel, semi-coal rocky tunnel and coal tunnel anchor aid, mainly suitable for underground complicated situations below the tunnel and bunker help. the product is used with resin anchors, its characteristics 1, fast boom of power, high energy, after installation can't best face up to the weight in a timely way, but also a massive anchoring force. 2, smooth to put in and function, low hard work intensity of workers, excessive support performance. 3, tons of coal aid charges are greatly decreased. 4. this product is primarily based on the mt146.2-2011 standards.

Product characteristics and structure identical strength rebar type resin anchor the principle fabric of the metallic body is preferred to be rebar with yield power greater than 335mpa, which integrates the mixing of resin anchoring agent and set up of the anchor rod, and is conducive to improving the set up pace and preloading force of the anchor rod. the specifications and fashions may be designed and selected according to extraordinary applications, geological situations and electricity requirements.

Principle of operation and installation of Equal Strength Threaded Anchor Rod

1.Working Principle.

Same-energy threaded metal kind resin anchor steel rod consists of rods made of different strength materials and their accessories collectively with matching resin anchoring agent. consistent with the design of anchoring duration, the rod frame might be inserted into the hollow wherein the anchoring agent is placed, after stirring, the anchoring agent will produce chemical response, and inside a certain time, the rod frame will be bonded with the coal and rock to be fixed inside the rock wall as an entire, and the threaded give up will be brought with the protective net and the bearing tray, and then tightened with the nut to reap the function of the aid, a good way to shape the high-power pre-stressing aid, and be able to manage the steadiness of roof slab, adapt to the motion of the peripheral rock, and efficaciously reduce to put off the off-lying, and solve the trouble of roof fall apart, if you want to reduce to put off the hassle of roof crumble. it is able to control the stability of the roof slab, adapt to the motion of the peripheral rock, correctly reduce or eliminate the separation, remedy the trouble of roof collapse, and includes a spread of guide paperwork and structures to form a prestressed guide machine, which realizes the mechanical installation and greatly improves the safety and reliability of the help.

2.Installation and use

(1), according to the design of the metal rod body and anchoring agent selection

(2) Drill holes in the anchoring substrate, and the diameter and depth of the holes should be matched with the specifications of the anchors.

(3) After drilling, use pressurized air or water to remove the floating dust in the hole and load the anchoring agent.

agent.

(4), the use of mixing equipment to drive the metal rod body, while stirring while advancing to the bottom of the hole, the mixing time should be less than the anchor solidifying agent gel time.

(5), in the waiting time do not make the rod body movement

(6), after the specified waiting time, can be on the tray spinning nut, bearing time reached, can test the tensile strength.

Product description of Equal Strength Threaded Anchor Rod

The uncooked material of identical-strength rebar anchor is product of steel with elongation of no longer much less than 15%, yield strength of now not much less than 335mpa, breaking energy of not much less than 490mpa, product of 20mnsi via warm lashing, and the compression resistance is 20 lots to 50 heaps respectively, and the straightness tolerance of φ18 to φ22 rods is much less than 2mm/m, and the straightness tolerance of φ16 rods is much less than 4mm/m. the sporting ability of the tail screw of rods should be less than 75% of the breaking pressure of the figure cloth of rods. it must be not much less than 75% of the breaking force of the determine fabric of the rod. anchor screw nut and proper-passed identical power resin anchor supporting the usage of the bottom end of the cylindrical column and 6 diamond/rectangular/runway-formed column of the combination of the nut body, the middle of the nut is ready with threaded holes, the diameter of the threaded frame is from the bottom of the sluggish growth within the shape of the frame, easy to install, the pressure is cheap, excessive power, corrosion-resistant, aesthetically beautiful appearance, the use of molding generation, manufacturing, manufacturing, production, and long service lifestyles of the product.

Technical Parameters of Equal Strength Threaded Anchor Rod

material | 20MnSi | ||||

Strength specifications | yield strength(MPa) | tensile strength(MPa) | elongation(%) | breaking load(KN/M) | Theoretical quality(KG/M)

|

φ16 | ≧335 | ≧490 | ≧16 | ≧100 | 1.6

|

φ18 | ≧335 | ≧490 | ≧16 | ≧126 | 2.0

|

Φ20 | ≧335 | ≧490 | ≧16 | ≧156 | 2.5

|

Φ22 | ≧335 | ≧490 | ≧16 | ≧189 | 3.0 |

Right-hand anchor/equal strength threaded steel anchor applicable conditions.

1.according to the design requirements to determine the placement of the anchor hole, use the eye drill, anchor drilling rig or coal electric powered drill to drill the hole, the depth is eighty-100mm shorter than the duration of the anchor rod.

2.use the compressed air pipe to attain into the lowest of the attention, through the compressed air, blow the rock dirt inside the hole.

3.diameter of drilling hole have to be 6-12mm larger than the diameter of anchor rod.

4.feed the drugs roll into the bottom of the attention with the anchor, start the integration device for mixing, and strictly manage the integration time in step with the requirement of resin anchor fixing agent.

5.after reaching the curing time, placed on the tray and tighten the nut.