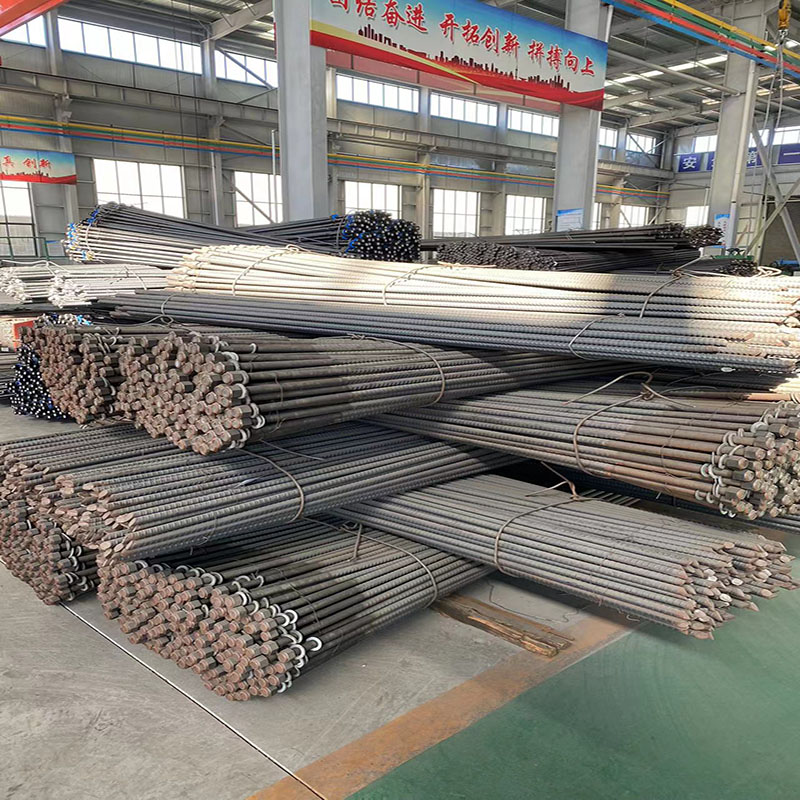

The Most Dazzling Deformed Steel Bars

Anchor rod product advantages:

Anchor rod full thread full length equal strength, than the same specification anchor rod bearing capacity increased by 40%; expand the scope of use of the anchor rod, can realize the end anchor, lengthening anchor and full anchor; easy to operate low price, etc.; threaded section strength is greater than the strength of the rod body, the threaded section of the flexural shear performance is good; high strength anchor rod, reasonable structure, top tightening force, able to automatically adjust the direction of the force, increase the binding force on the rock, and can be realized by mechanization and fast Installation; can be end anchor, extension anchor and full anchor, mainly used for high strength support of high deformation roadway in high ground pressure mine.

Product Description:

Left-hand and right-hand anchors implement MT146.2-2011 standard, which is the most basic part of the tunnel support in contemporary coal mines, he will be bound together with the surrounding rock of the tunnel, so that the surrounding rock supports itself. Nowadays, anchor rods are not only used in mines, but also used in engineering technology to actively reinforce slopes, tunnels and dams. Anchor as a deep stratum of the tensile member, it is connected with the engineering structures at one end, the other end of the deep stratum, the whole anchor is divided into the free section and anchorage section, the free section is the anchor head of the tensile force to the anchor solid area, its function is to apply prestressing force to the anchor; anchorage section refers to the cement paste will be prestressing tendon bonded with the soil layer of the region, its function is to increase the friction effect of the anchorage solid bonded with the soil layer, increase the anchor solid pressure-bearing effect, will be the anchor of the soil layer, and will be the anchor of the soil layer, the anchor of the soil layer. Its function is to increase the bonding friction between the anchor solid and the soil layer, increase the pressure-bearing effect of the anchor solid, and transmit the tension of the free section to the depth of the soil.

Mining anchor is a kind of anchor commonly used in coal mine underground support with the traditional metal anchor compared to its quality and solid full length and other strong length can be intercepted according to the specific needs of the rod easy to cut the operation is simple and convenient so that you do not make it difficult to use so that the roadway and other construction sites are very favorable to the safety and construction.

parameters

yield load(KN) | breaking load(KN) | |||||||

Strength Specification | calibre(mm) | BHRB335 | BHRB500 | BHRB600 | BHRB335 | BHRB500 | BHRB600 | Theoretical qualitykg/m |

φ16 | 16

| 67 | 100 | - | 99 | 133 | - | - |

φ18 | 18

| 85 | 127 | - | 125 | 168 | - | - |

Φ20 | 20

| 105 | 157 | 190 | 155 | 210 | 260 | 2.47 |

Φ22 | 22 | 125 | 190 | 230 | 185 | 250 | 310 | 2.98 |

Working Principle:

Longitudinal ribless rebar type resin anchor is used to support through the cooperation of metal rod body and resin anchoring agent. Firstly, the metal rod body is inserted into the hole pre-filled with resin anchoring agent, after stirring, the resin anchoring agent will produce chemical reaction within a certain period of time, which will bond the rod body with the coal rock and fix it in the rock wall. Then the protection net and tray are added to the threaded end of the rod and tightened with nuts to achieve the supporting effect. Through the formation of high-strength prestressing support to stabilize the roof plate, reduce the off-seam and solve the problems of collapsing and bubbling.

Installation:

1.Select suitable metal rod body and anchoring agent according to the design requirements.

2.Drill holes in the designated location, ensuring that the hole diameter and depth match the anchor specifications.

3.Remove floating dust in the hole after drilling, and then load the anchoring agent.

4.Use a mixer to agitate the metal rod and push it to the bottom of the hole, the agitation time needs to be less than the anchoring agent gel time.

5.Avoid moving the rod while waiting for the curing process.

6.After waiting for the specified time, the pallet can be installed and the nut can be tightened, and the tensile strength can be tested when the load bearing time is reached.

Storage and Transportation:

Store resin anchor metal rod body should be placed in a dry place, the anchoring section should not be subjected to oil, the threaded section needs to take measures to prevent rust.

Every 5 rods as a group, bundled and fixed with a certificate of conformity.

Avoid collision and nut falling off during transportation to ensure the integrity of the rods.

Enhance protection measures during transportation and stack the rods neatly.

The company mainly supplies the following products:

16#No longitudinal rib (equal strength) threaded anchor, 18#No longitudinal rib (equal strength) threaded anchor, 20#No longitudinal rib (equal strength) threaded anchor, 22#No longitudinal rib (equal strength) threaded anchor, 24#No longitudinal rib (equal strength) threaded anchor.

Product Qualification