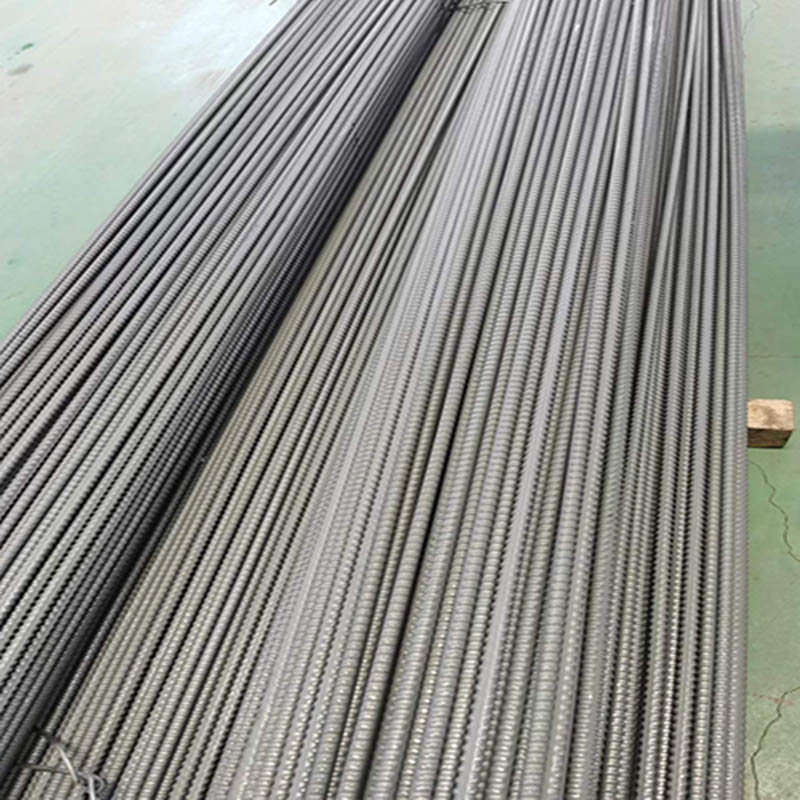

Rock And Bolt Rebar

Dominance:

Rock And Bolt Rebar offers a range of high-quality rebar products with superior strength and durability, making them ideal for various construction projects. The Canadian Tire Rebar, specifically designed by Rock And Bolt, stands out for its excellent performance and reliability. Its advanced technology ensures a secure and stable foundation, providing peace of mind to builders and contractors. With Rock And Bolt Rebar, you can trust that your structures will be well-supported and built to last. Choose the Canadian Tire Rebar for a reliable and efficient construction solution.

Descriptive:

Rock And Bolt Rebar is a leading provider of high-quality construction materials, specializing in innovative and durable solutions for various building projects. Our High Strength Rebar is designed to meet the demanding requirements of modern construction, offering superior tensile strength and reliability. Central Rebar, a trusted distributor of Rock And Bolt Rebar products, ensures that builders have access to top-notch materials for their projects. Our rebar products are manufactured using advanced technology and quality control processes to ensure consistency and performance. Whether you are working on a small-scale renovation or a large commercial development, Rock And Bolt Rebar provides the strength and durability needed to support your structures. Choose Central Rebar for all your rebar needs and build with confidence.

Weight of left and right rotating anchors

Strength specifications | Calibre (mm) | Theoretical weight kg/m(levitra) | Theoretical weight kg/m(right-hand side) |

Φ16 | 16 | 1.24 | 1.47 |

Φ18 | 18 | 2.12 | 1.88 |

Φ20 | 20 | 2.6 | 2.38 |

Φ22 | 22 | 3.11 | 2.91 |

Rebar Anchor Description:

Rebar anchor is a key support material, which plays an important role in modern mining and engineering technology. It is categorized into two types: left-handed and right-handed, and conforms to MT146.2-2011 standard. Rebar anchors play a key role in roadway support, binding the surrounding rock firmly and realizing the support of the surrounding rock itself. Besides being widely used in the mining field, rebar anchors are also used for active reinforcement of slopes, tunnels, dams and other projects. As a member bearing tensile force, it is divided into free and anchored sections, utilizing pre-stressing and bonding friction to enhance the bearing capacity of the soil body and ensure a solid and reliable support system.

Rebar anchors are divided into longitudinal ribless rebar resin anchors (referred to as left-handed anchors) and equal-strength rebar resin anchors (referred to as right-handed anchors). Left-hand and right-hand anchors implement the MT146.2-2011 standard, which is the basic component of tunnel support in contemporary coal mines, binding the surrounding rock of the tunnel together, so that the surrounding rock supports itself. Nowadays, anchors are not only used in mines, but also used in engineering technology to actively reinforce slopes, tunnels and dams. Anchor as a deep stratum of the tensile member, it is connected with the engineering structures at one end, the other end of the deep stratum, the whole anchor is divided into the free section and anchorage section, the free section is the anchor head of the tensile force to the anchor solid area, its function is to apply prestressing force to the anchor; anchorage section refers to the cement paste will be prestressing tendon bonded with the soil layer of the region, its function is to increase the friction effect of the anchorage solid bonded with the soil layer, increase the anchor solid pressure-bearing effect, will be the anchor of the soil layer, and will be the anchor of the soil layer, the anchor of the soil layer. Its function is to increase the bonding friction between the anchor solid and the soil layer, increase the pressure-bearing effect of the anchor solid, and transmit the tension of the free section to the depth of the soil.

Rebar anchor use:

Generally applicable to mine roadway, bridge tunnel, track slope protection, etc. to strengthen the support, the general anchor hole is to use the anchor drilling rig to drill holes, and then put the appropriate anchoring agent (resin medicine roll), and then use the anchor drilling rig and other tools to drill the anchor into the anchor hole to the anchoring agent for stirring anchoring, and then use the anchor drilling rig and other tools to install the nut;

Anchor Technical Characteristics

Anchor according to the diameter to be classified, generally the most commonly used are: 16mm, 18mm, 20mm, 22mm; anchor rod body can be realized with the anchor hole diameter, resin maki diameter better match, with strong anchor force, high elongation, safe and reliable, high quality and low consumption, easy to use and so on.

Anchor material description.

High-strength anchor raw materials are made of steel with elongation not less than 15%, yield strength not less than 335MPa, breaking strength not less than 490MPa, made of 20MnSi steel by hot lashing, with compression resistance from 20 tons to 50 tons, straightness tolerance of Φ18 to Φ22 rods is ≤2mm/m, and the straightness tolerance of Φ16 rods is less than 4mm/m. The carrying capacity of the tail thread of rods should be not less than the breaking strength of the parent material of rods, which is not less than the breaking strength of the parent material of rods. The load carrying capacity of the screw thread at the end of the rod should be not less than 75% of the breaking force of the mother material of the rod.

Installation conditions.

1, Determine the anchor hole position, use appropriate equipment such as eye drills, anchor drills or coal drills to drill the holes, make sure the depth is 80-100mm shorter than the length of the anchor.

2、Use compressed air pipe to send compressed air into the hole to clean the rock dust in the hole.

3、Make sure the diameter of the hole is 6-12mm larger than the diameter of the anchor.

4、Feed the pre-prepared medicine roll into the drill hole, start the mixing device to mix, and strictly control the mixing time to meet the requirements of resin anchor fixing agent.

5、After waiting for the curing time, install the tray and tighten the nut to make sure the installation is firm and reliable.