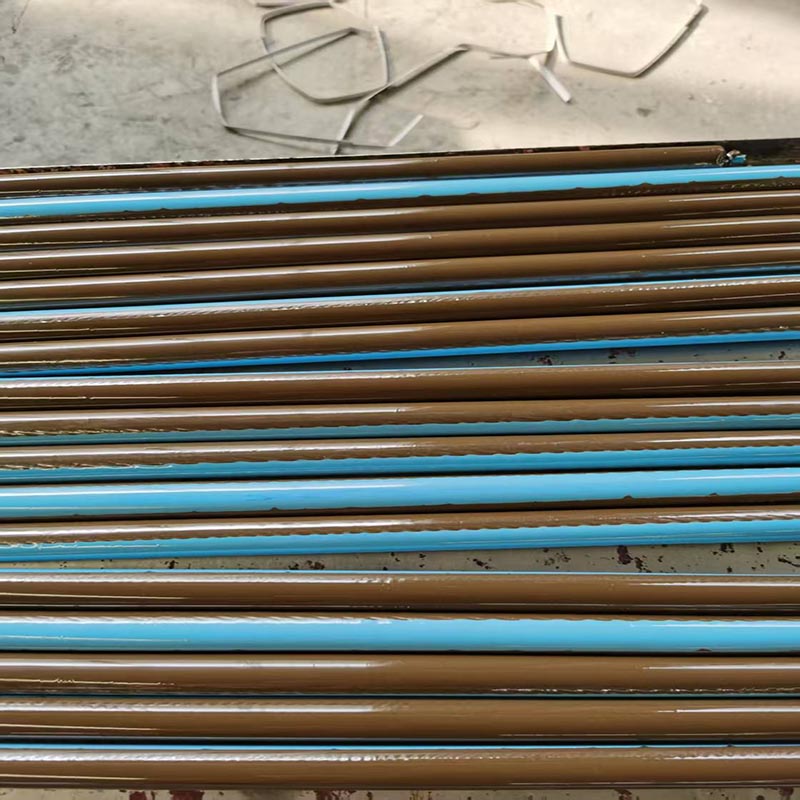

Fast Drying Resin Capsules

Advantage:

Resin Capsules From China, particularly the 2360 Reinforced Anchor Bolt Resin, offer unparalleled advantages in construction and mining applications. These Resin Capsules Made In China are engineered for fast drying, ensuring rapid and secure anchoring in various substrates. Their high-strength formulation provides exceptional load-bearing capacity, making them ideal for reinforcing structures and stabilizing rock formations. Manufactured with precision, these resin capsules deliver consistent performance, even in challenging environments. By choosing Resin Capsules From China, you benefit from cost-effective, reliable, and durable solutions that enhance project efficiency and safety. Trust in the quality of Made In China products for superior anchoring results.

Product Description:

Fast Drying Resin Capsules, a leading Resin Anchoring Agent, are engineered to provide superior performance in construction, mining, and infrastructure projects. These Resin Capsules Made In China are designed for rapid curing, ensuring quick and secure anchoring in various substrates such as concrete, rock, and masonry. The fast-drying feature significantly reduces installation time, enhancing project efficiency while maintaining exceptional strength and durability.

Each capsule contains a precise blend of high-quality resin and hardener, ensuring consistent and reliable bonding. The robust design of Fast Drying Resin Capsules makes them ideal for critical applications, including reinforcing structures, securing anchor bolts, and stabilizing tunnels. Their ability to withstand heavy loads and harsh environmental conditions makes them a trusted choice for professionals worldwide.

Manufactured with advanced technology, Resin Capsules Made In China meet international quality standards, offering cost-effective and eco-friendly solutions. Whether for industrial or commercial use, these capsules deliver unmatched performance, making them an essential component for modern anchoring needs. Trust in the precision and innovation of Chinese manufacturing for reliable, high-performance resin capsules.

Specification

Commonly used specifications: | ||||

norm | Diameter X Length (mmxmm) | theoretical weight(g) | Applicable drilling holes (mm) | Number of sticks per carton |

3530 | φ35x300 | 550±10 | φ42±2 | 40 |

3537 | φ35x370 | 700±10 | φ42±2 | 40 |

3540 | φ35x400 | 800±10 | φ42±2 | 40 |

2835 | φ28x350 | 400±10 | φ32±2 | 40 |

2850 | φ28x500 | 640±10 | φ32±2 | 40 |

2335 | φ23x350 | 300±10 | φ28±2 | 50 |

2350 | φ23x500 | 420±10 | φ28±2 | 50 |

Special specifications can be produced according to user requirements | ||||

Product Description:

This product has long shelf life, high anchoring strength, convenient construction and other excellent performance. It can be used with metal or FRP anchors, and is widely used in underground engineering, slope support, equipment installation of vertical wells, connection of building components, anchoring of equipment foundations, etc. It is the best anchoring material in modern anchoring engineering. It can be used with metal or FRP anchors, and is widely used in underground engineering, slope support, equipment installation of vertical wells, component connection of buildings, and anchoring of equipment foundations. It is an excellent anchoring material in modern anchoring project.

Resin anchors are not only used in shaft support, shaft installation, pre-stressing anchor reinforcement for water and electricity projects, but also in building reinforcement, highway repair, tunneling, foundation rooting, equipment foundation and component anchoring, etc. It has its wide range of applications in the field.

Product Material:

Made of synthetic resin, curing agent, accelerator, etc. according to a certain ratio.

Performance indexes.

Compressive strength:≥60MPa

Shear strength:≥35MPa

Adhesive strength: for rebar>16MPa for concrete>7MPa

Volume:1.9-202g/cm3

Modulus of elasticity:≥1.6x104MPa

Poisson's ratio:≥0.3

Vibration fatigue:>8 million times

Storage period:<25C3 months

Environment:-30℃~+60C

Product Qualification