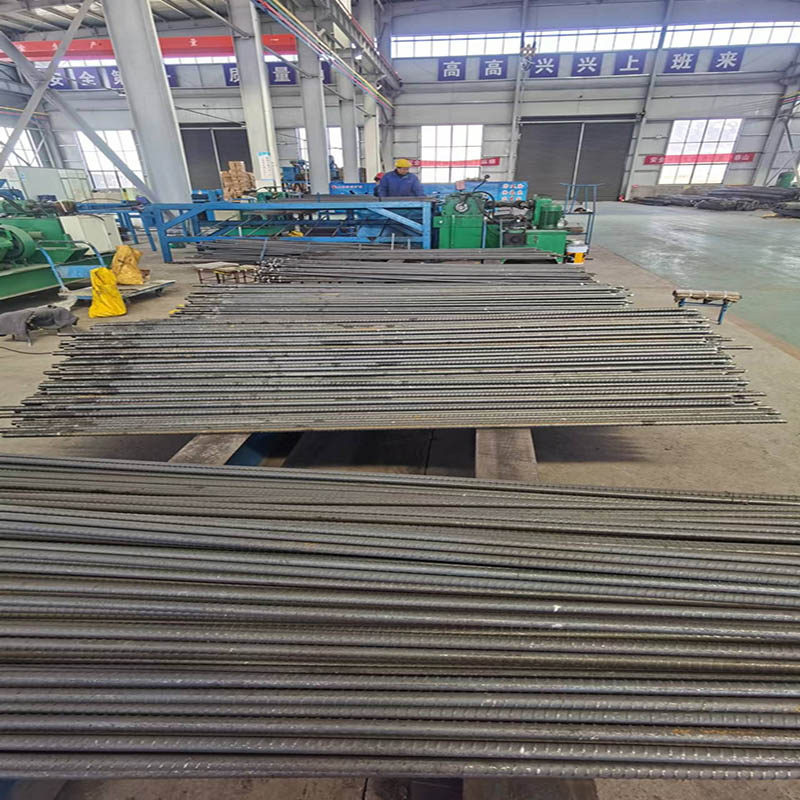

Threaded Rod Anchor Concrete

Reinforcing steel is a building material used to strengthen concrete structures, usually in the form of long strips. It has high strength and durability, which can help concrete structures withstand greater loads and improve seismic performance. Reinforcing bars are generally categorized into two types: plain bars and rebars, which have surface threads for better bonding with concrete. In construction, the type, diameter and quantity of Rebar are selected and used based on the design requirements and structural load carrying capacity needs.

Reinforcement Steel

Reinforcing steel is a commonly used construction material that is usually used to reinforce concrete structures. In construction projects, rebar can enhance the strength and toughness of concrete and improve the stability and load-bearing capacity of the structure. Reinforcing bars come in different sizes and models, and the appropriate specifications and quantities of reinforcing bars are selected for construction according to the project design requirements。

Anchor technical parameters:

Technical Parameters | ||||||||

Performance Material Specification | Outer diameter of rod (mm) | carrying capacity(kn) | ||||||

Nominal size | tolerance | HRB335 | HRB400 | HRB500 | HRB600 | HRB335 | ||

norm | carrying capacity | |||||||

φ-16 | 16 | +0.3/-0 | ≧100 | ≧120 | ≧135 | 120x120x5 | ≧100 | |

φ-18 | 18 | +0.3/-0 | ≧126 | ≧150 | ≧172 | ≧206 | 150x150x5 | ≧135 |

φ-20 | 20 | +0.3/-0 | ≧157 | ≧180 | ≧210 | ≧260 | 150x150x6 | ≧170 |

φ-22 | 22 | +0.3/-0 | ≧190 | ≧225 | ≧250 | ≧310 | 150x150x8 | ≧230 |

Product Details

Rebar anchors are divided into longitudinal ribless rebar resin anchors (referred to as left-handed anchors) and equal-strength rebar resin anchors (referred to as right-handed anchors). Anchor advantages, strong anchor force, high elongation, safety and reliability, high quality and low consumption, easy to use and other advantages.

Left-hand and right-hand anchors implement the MT146.2-2011 standard, which is the most basic part of the roadway support in contemporary coal mines, and it binds the surrounding rocks of the roadway together, so that the surrounding rocks support themselves. Nowadays, anchor rods are not only used in mines, but also used in engineering technology to actively reinforce slopes, tunnels and dams. Anchor as a deep stratum of the tensile member, it is connected with the engineering structures at one end, the other end of the deep stratum, the whole anchor is divided into the free section and anchorage section, the free section is the anchor head of the tensile force to the anchor solid area, its function is to apply prestressing force to the anchor; anchorage section refers to the cement paste will be prestressing tendon bonded with the soil layer of the region, its function is to increase the friction effect of the anchorage solid bonded with the soil layer, increase the anchor solid pressure-bearing effect, will be the anchor of the soil layer, and will be the anchor of the soil layer, the anchor of the soil layer. Its function is to increase the bonding friction between the anchor solid and the soil layer, increase the pressure-bearing effect of the anchor solid, and transmit the tension of the free section to the depth of the soil. Anchor structure: rod body, anchor disk, ball washer, friction washer, nut. Generally applicable to mine roadway, bridge tunnel, track slope protection, etc. to strengthen the support, the general anchor hole is to use the anchor drilling rig to drill holes, and then put the appropriate anchoring agent (resin medicine roll), and then use the anchor drilling rig and other tools to drill the anchor into the anchor hole to the anchoring agent for stirring anchoring, and then use the anchor drilling rig and other tools to the installation of its nut.

Anchor material description.

High-strength anchor raw materials used in the elongation of not less than 15%, yield strength of not less than 335MPa, breaking strength of not less than 490MPa, the material of 20MnSi steel by hot lashing from 20 tons to 50 tons of compression respectively, Φ18 to Φ22 rod straightness tolerance ≤ 2mm / m, Φ16 rod straightness tolerance is less than 4mm / m. The rod tail thread bearing capacity should be not less than 75% of the rod parent material breaking force . The load carrying capacity of the screw thread at the end of the rod should be not less than 75% of the breaking force of the mother material of the rod.

Anchor use method.

1. Determine the anchor hole position according to the design requirements, and drill the hole with drilling rig.

2.Blow out the rock dust in the hole with pressurized air.

3. Send the anchoring agent to the bottom of the hole, hold it against the anchor and start mixing (mixing time is specified according to the type of the anchoring agent), after mixing, unload the mixing tool, after reaching the waiting time, unload the mixing connecting head, put on the anchor plate, ball washer, friction washer, and tighten the nut with a wrench.

Company Environment