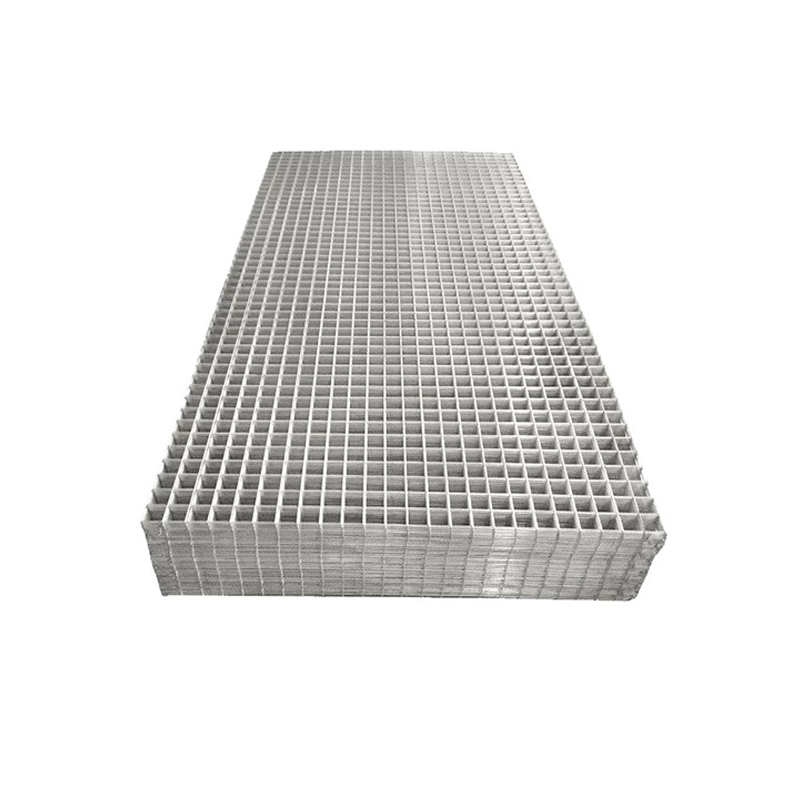

Welded Wire Mesh 6x6

The welded cord mesh is a recreation-changer in contemporary production, presenting unrivaled strength, versatility, and efficiency. Its ability to enhance safety, reduce cracking, and reinforce concrete structures make it an indispensable component in construction projects of all scales. Whether it is a residential building, a commercial complex, or a large-scale infrastructure mission,Welded Wire Mesh provides a solid foundation for long-lasting and robust structures. Embrace the welded cord mesh and witness the transformation of construction excellence, reinforcing your imaginative and prescient with power and sturdiness for a brighter and safer destiny.

Material: low carbon steel wire, electric galvanized wire, hot galvanized wire, re-drawn wire.

Advantages: firm welding, uniform mesh, flat mesh surface,corrosion resistance, high electricity, strong defensive ability.

Classification by material: stainless steel Wire Mesh, black iron wire mesh.

According to the use can be public:Ornamental mesh, fashioned mesh, greenhouse seedbed cord mesh, fence mesh, construction mesh and so forth.

Welded Wire Mesh 6x6: Reinforcing Excellence in Construction

Introduction of Welded Wire Mesh 6x6

Introducing the Welded Wire Mesh, a versatile and reliable solution that has redefined construction reinforcement. This innovative product is manufactured by fusing steel wires together through a high-precision welding process, creating a strong and durable mesh structure. Welded Wire Mesh offers an array of applications across various construction projects, providing robust support, safety, and efficiency. Let's delve into the details and benefits that make Welded Wire Mesh an essential component in modern construction.

Robust Construction and Versatility of Welded Wire Mesh 6x6

Welded Wire Mesh is crafted from high-quality steel wires that are precisely welded together at intersecting points. This welding process ensures superior structural integrity, allowing the mesh to withstand heavy loads and forces. With a wide range of mesh sizes and wire gauges available, Welded Wire Mesh can be tailored to suit different construction needs, making it a versatile choice for various applications.

Cost-Effective Solution of Welded Wire Mesh 6x6

Welded Wire Mesh offers an excellent cost-to-benefit ratio, making it an economical choice for construction projects. Its high strength and efficiency reduce the need for additional reinforcement, thus saving on materials and labor costs. Moreover, the ease of installation further contributes to overall cost savings and faster project completion.The Welded Wire Mesh's modular design allows for easy handling and installation. The mesh can be easily cut to the required dimensions, making it adaptable to various project requirements. Its flexible nature ensures a smooth installation process, saving time and labor on-site.

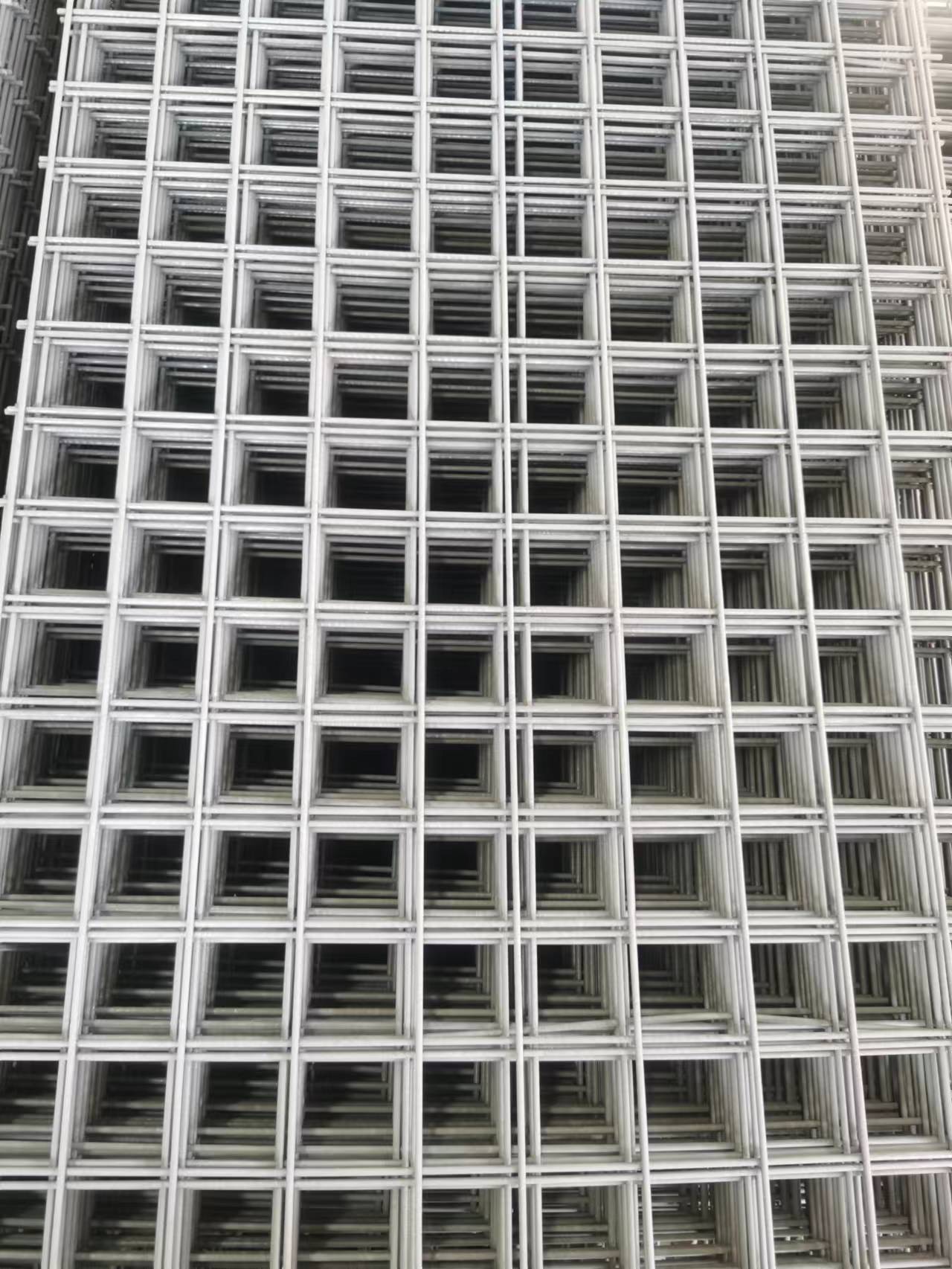

Item | Size |

Wire Diameter | 3mm, 4mm, 5mm, 6mm,or as customer’s request |

Hole size/Opening/Aperture | 100x100mm,150x150mm,200x200mm,or as customer’s request |

Mesh Width | 600mm, 1200mm, 1800mm, 2400mm,or as customer’s request |

Mesh Length | 1-6meters |

Strength and Safety Enhancement of Welded Wire Mesh 6x6

The Welded Wire Mesh acts as a reinforcing framework in concrete structures, providing tensile strength and reducing cracking. Its uniform grid pattern evenly distributes loads, increasing the overall stability and load-bearing capacity of concrete. As a result, it significantly improves the safety and longevity of construction projects, minimizing the risk of structural failures and enhancing overall safety for workers and users.

Corrosion Resistance and Durability of Welded Wire Mesh 6x6

Welded Wire Mesh is often galvanized or coated to enhance its resistance to corrosion, ensuring longevity and durability in harsh environments. This protective coating ensures that the mesh maintains its structural integrity and performance over time, reducing the need for frequent maintenance and replacements.Welded Wire Mesh finds applications in various construction projects, including concrete slabs, walls, columns, and precast elements. Additionally, it is commonly used in road pavements, bridge decks, and retaining walls, reinforcing critical infrastructure projects.

Advantages of Welded Wire Mesh 6x6

1. enhance the crack resistance of concrete

The crossing points of manual steel wire binding are easy to slide, the binding force of steel bars and concrete is weak, and it is easy to produce cracks, and the welding mesh solder joints can not only withstand pressure, but also withstand shear. The vertical and horizontal steel bars form a network structure to bond and anchor together. When the welded steel bars adopt a smaller diameter and a dense spacing, due to the increase of welding points per unit area, it is more conducive to enhancing the crack resistance of concrete and reducing the crack occurrence by more than 75%.

2. Save time

The use of welding wire mesh saves a lot of field lashing labor and construction site, can be civilized construction, so that the quality of steel bar engineering is significantly improved, because the welding mesh is prefabricated in the factory in advance, the site does not need to be reprocessed, no steel waste head, due to shorten the construction period, thereby reducing the cost of lifting machinery.

3. Save steel

Compared with the use of Grade I rebar, the design strength of ribbed steel mesh is about 70% higher than that of grade I rebar, and after considering some structural requirements, steel can still be saved by more than 25%.